Woodwork screws are essential components in the world of woodworking, offering strength, durability, and ease of use. Whether you’re a seasoned woodworker or just starting out, understanding the various types of woodwork screws and their applications is crucial for creating high-quality, lasting projects. In this comprehensive guide, we’ll delve into everything you need to know about woodwork screws, from types and materials to tips and tricks for optimal use.

Introduction to Woodworking Screws

When it comes to woodworking, screws are often the unsung heroes. These small but mighty fasteners hold your projects together, ensuring stability and longevity. Moreover, woodwork screws come in various shapes, sizes, and materials, each designed for specific tasks. By choosing the right screw for the job, you can enhance the strength and aesthetics of your work.

Types of Woodwork Screws

There are numerous types of woodwork screws, each with its unique features and applications. Here are some of the most common ones:

1. Wood Screws

Wood screws are the most commonly used screws in woodworking. They have a sharp, pointed tip that allows them to penetrate wood easily. Additionally, wood screws come in various lengths and diameters, making them versatile for different projects.

2. Deck Screws

Deck screws are designed specifically for outdoor projects, such as building decks and fences. They are made from corrosion-resistant materials, such as stainless steel or coated steel, to withstand the elements. Consequently, they are ideal for outdoor use.

3. Drywall Screws

Although primarily used for securing drywall, these screws are also handy in woodworking. Drywall screws have a bugle-shaped head that prevents the screw from tearing through the material, making them ideal for thin or delicate wood.

4. Lag Screws

Lag screws, also known as lag bolts, are heavy-duty screws used for structural applications. They have a hex head and require a wrench for installation. Therefore, lag screws are perfect for projects that need extra strength, such as securing large beams or posts.

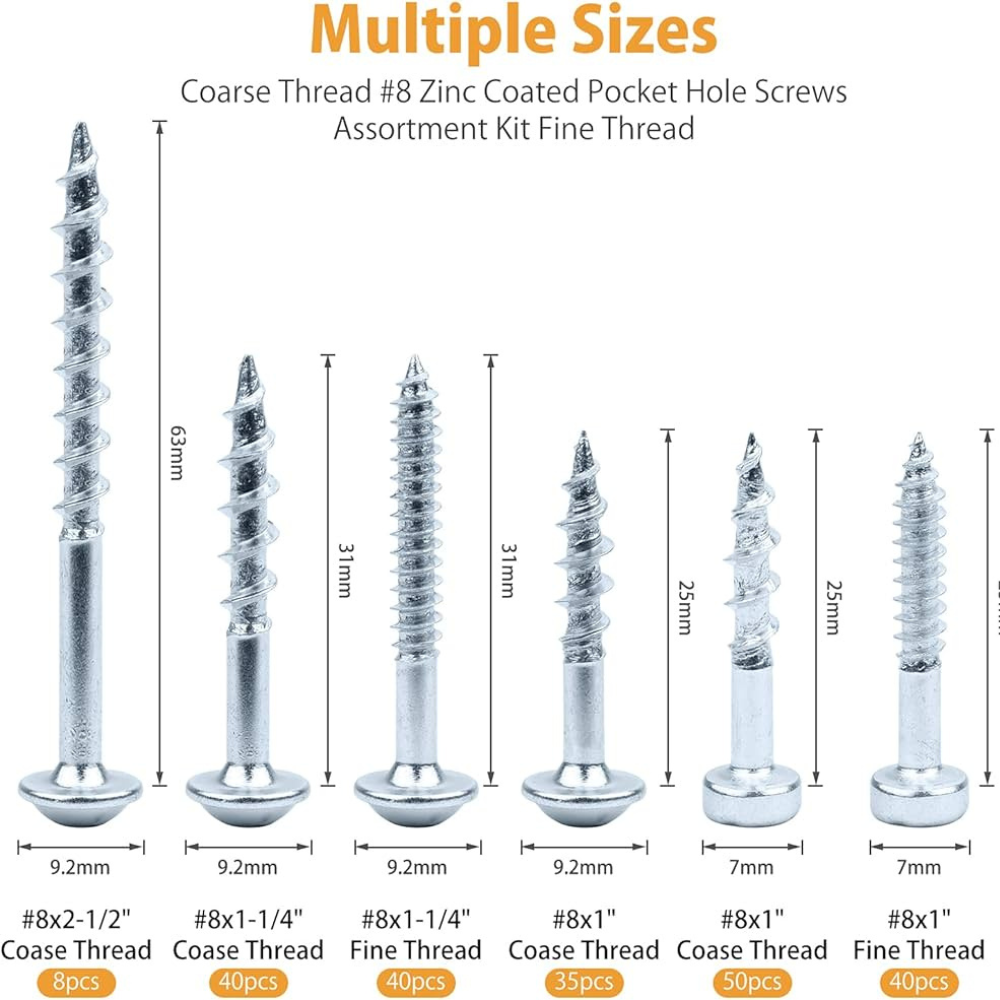

5. Pocket Hole Screws

Pocket hole screws are specifically designed for pocket hole joinery. They have a self-tapping tip and a flat washer head, which helps draw the joint tight. Consequently, these screws are essential for creating strong, hidden joints.

Materials Used when using Woodwork Screws

The material of the screw is just as important as its type. The right material ensures durability and longevity, especially in challenging environments.

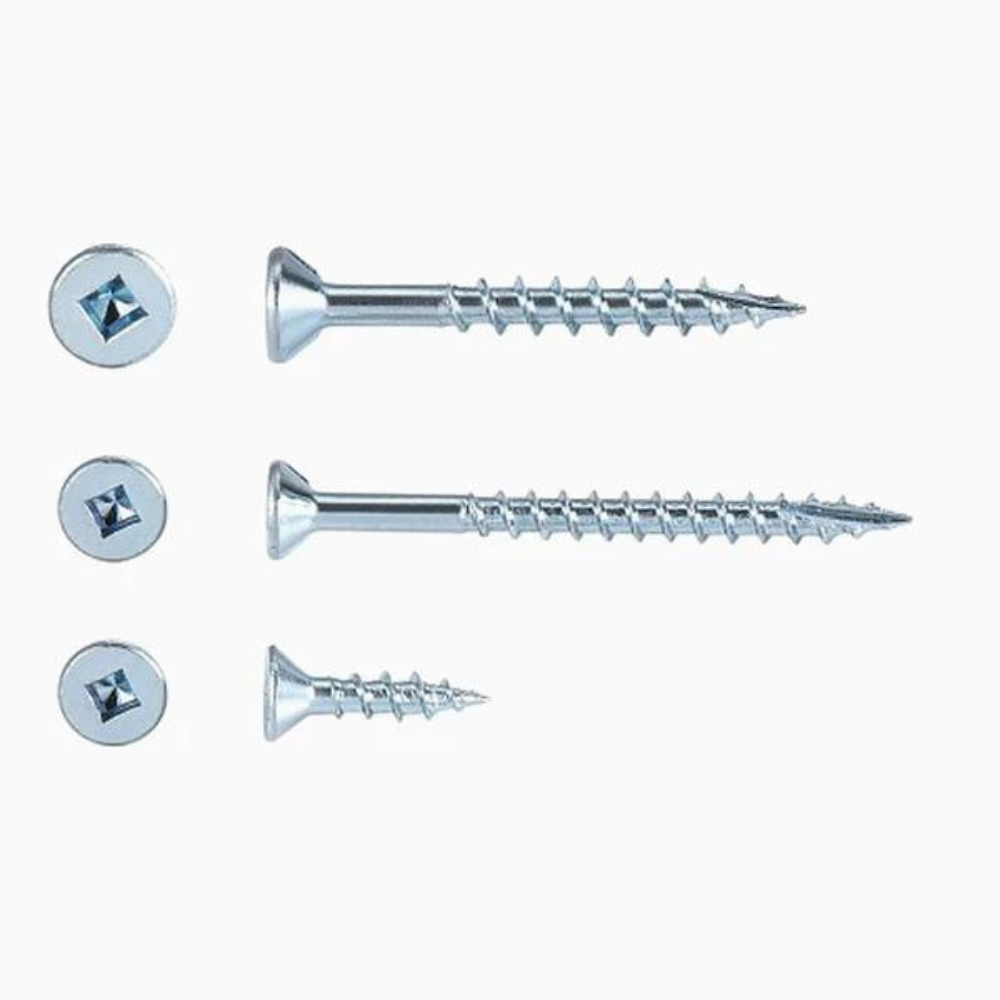

6. Steel Screws

Steel screws are the most common and affordable option. They are strong and versatile, suitable for most indoor woodworking projects. However, they may rust if exposed to moisture. Therefore, they are best for indoor use.

7. Stainless Steel Screws

Stainless steel screws are highly resistant to corrosion, making them ideal for outdoor and high-moisture environments. They are more expensive than regular steel screws but offer superior durability. Hence, they are a worthwhile investment for long-term projects.

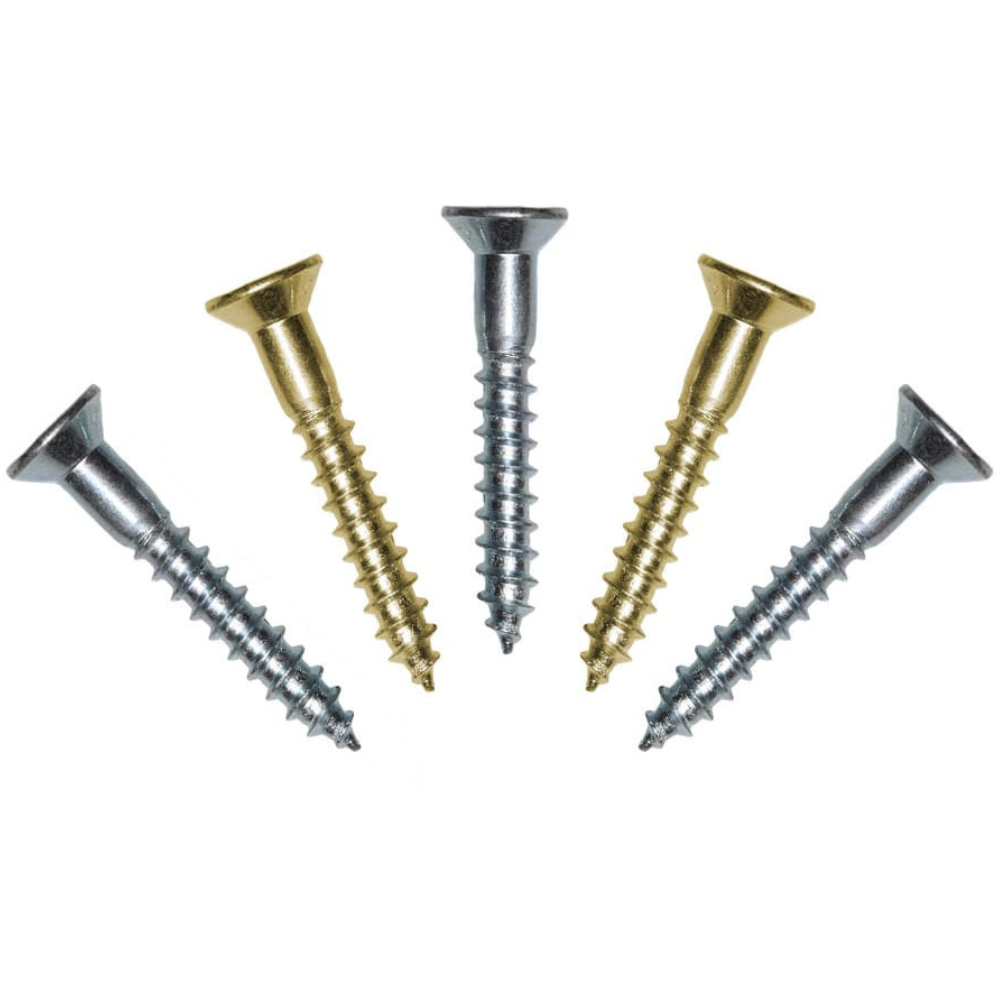

8. Brass Screws

Brass screws are known for their aesthetic appeal, often used in decorative woodworking projects. They are softer than steel and stainless steel, so they require pre-drilling to avoid snapping. Nevertheless, their beauty makes them a favorite for fine woodworking.

9. Zinc-Plated Screws

Zinc-plated screws are coated with a layer of zinc to prevent rust. They offer a good balance between cost and corrosion resistance, suitable for both indoor and outdoor use. As a result, they are quite versatile.

Choosing the Right Screw for Your Project

Selecting the appropriate woodworking screw for your project involves considering several factors, such as the type of wood, the environment, and the load the joint will bear.

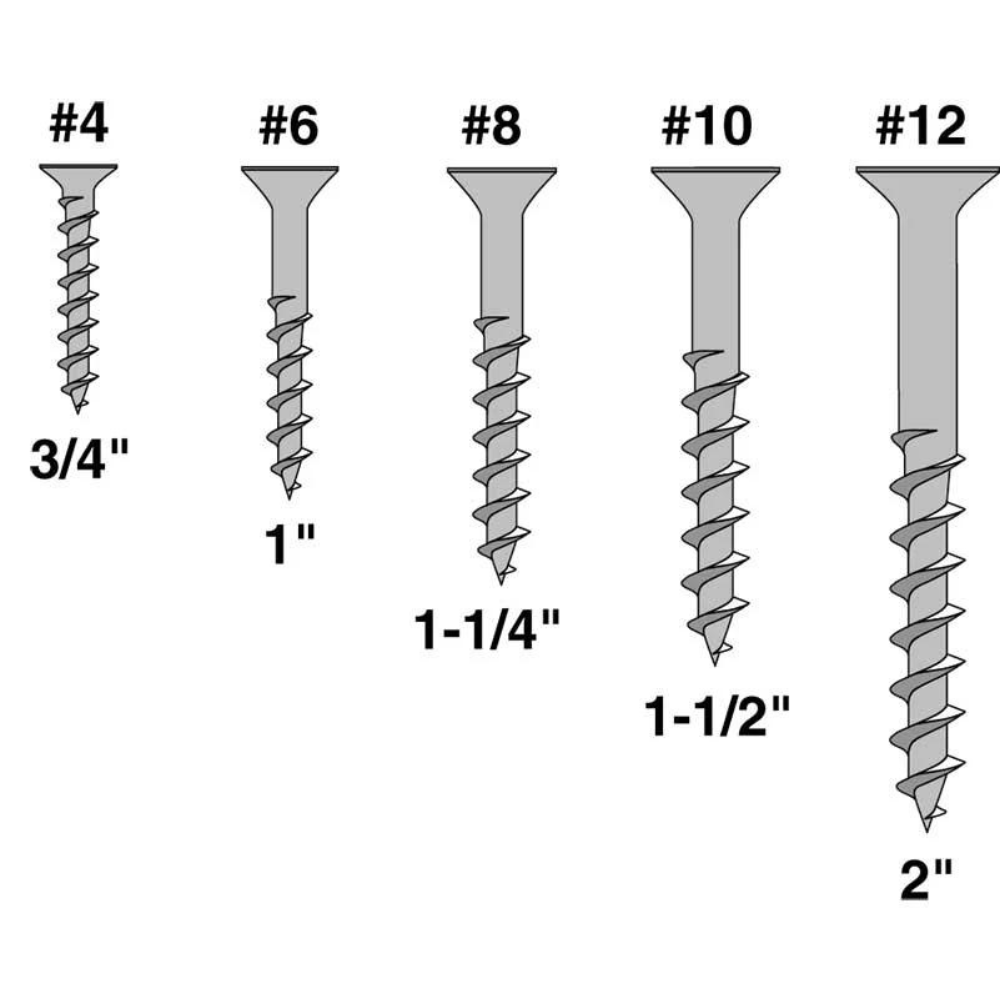

10. Consider the Wood Type

Different woods have varying densities and properties. For softwoods like pine, use screws with coarse threads to ensure a firm grip. For hardwoods like oak, fine-thread screws are preferable to avoid splitting the wood. Consequently, you’ll achieve better results.

11. Think About the Environment

For outdoor projects or high-moisture areas, choose screws made from corrosion-resistant materials like stainless steel or zinc-plated steel. This will prevent rust and ensure the longevity of your project. Thus, your work will withstand harsh conditions.

12. Assess the Load

For heavy-duty applications, such as securing structural components, use lag screws or other heavy-duty screws. For lighter tasks, wood screws or drywall screws may suffice. Therefore, always match the screw type to the task.

Tips for Using Woodworking Screws

Using woodworking screws effectively can make a significant difference in the quality and durability of your projects. Here are some tips to help you get the most out of your screws:

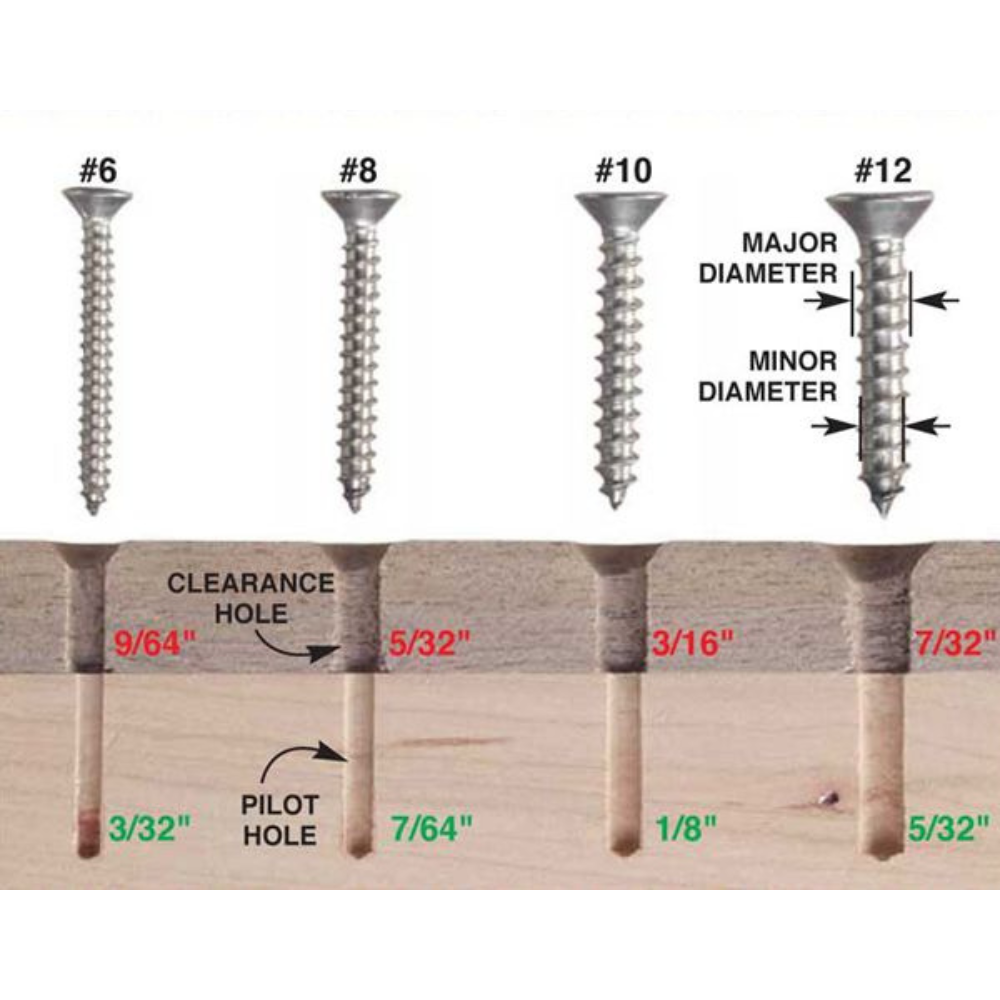

13. Pre-Drill Pilot Holes

Pre-drilling pilot holes helps prevent the wood from splitting and makes it easier to drive the screw. The pilot hole should be slightly smaller than the screw’s diameter. Consequently, this simple step can save you time and frustration.

14. Use Countersink Bits

Countersink bits create a recess for the screw head, allowing it to sit flush with or below the wood surface. This not only improves the appearance of your project but also prevents the wood from splitting. Therefore, your finished product will look more professional.

15. Choose the Right Screw Length

The length of the screw should be at least twice the thickness of the wood you’re joining. This ensures a strong, secure connection. Hence, always double-check the screw length before starting.

16. Apply Steady Pressure

When driving screws, apply steady, even pressure to avoid stripping the screw head. Use a screwdriver or drill with the appropriate bit for the screw type. As a result, you’ll achieve a more secure fit.

For your “Free”Guide to 13 Wood Joinery Types – Click Here.

Common Mistakes to Avoid

Even experienced woodworkers can make mistakes when using screws. Here are some common pitfalls to watch out for:

17. Over-Tightening Screws

Over-tightening can strip the screw head or damage the wood. Therefore, tighten the screw just enough to secure the joint without causing damage. This will help maintain the integrity of your project.

18. Using the Wrong Screw Type

Using the wrong screw type can lead to weak joints or damaged wood. Always choose the right screw for the specific task and material. Consequently, your work will be stronger and more reliable.

19. Neglecting Corrosion Resistance

For outdoor projects, using non-corrosion-resistant screws can lead to rust and failure of the joint. Thus, always consider the environment when selecting screws. This simple step can significantly extend the life of your project.

The Evolution of Woodworking Screws

The design and materials of woodworking screws have evolved significantly over time. Modern screws offer improved strength, ease of use, and resistance to environmental factors.

20. Early Woodworking Screws

Early screws were handmade and often inconsistent in quality. They were typically made from iron and required pre-drilled holes. As a result, they were less reliable than today’s screws.

21. Industrial Revolution and Mass Production

The Industrial Revolution brought mass production techniques, making screws more affordable and consistent in quality. Consequently, the introduction of machine-made screws revolutionized woodworking.

22. Modern Innovations

Today’s screws are designed with advanced features, such as self-tapping tips and corrosion-resistant coatings. Consequently, these innovations make woodworking easier and more efficient.

Woodworking Screws in Different Projects

Woodworking screws play a crucial role in a variety of projects, from furniture making to large outdoor structures.

23. Furniture Making

In furniture making, screws are used to join pieces securely without visible fasteners. Pocket hole screws and dowel screws are popular choices for this purpose. Therefore, they are essential in crafting beautiful and durable furniture.

24. Cabinetry

Cabinet makers often use screws for assembling and mounting cabinets. Confirmat screws are specially designed for this task, providing a strong, tight joint. Consequently, they ensure the longevity and stability of cabinetry.

25. Outdoor Structures

For outdoor structures like decks and fences, corrosion-resistant screws are essential. Deck screws and lag screws provide the necessary strength and durability. As a result, your outdoor projects will withstand the test of time.

Maintaining and Storing Woodworking Screws

Proper maintenance and storage of your woodworking screws can extend their lifespan and keep them ready for use.

26. Keep Screws Organized

Organize your screws by type and size in a storage container with labeled compartments. This makes it easy to find the right screw for your project. Consequently, you’ll save time and reduce frustration.

27. Store in a Dry Place

Moisture can cause screws to rust, especially if they are not made from corrosion-resistant materials. Therefore, store your screws in a dry, climate-controlled environment. This will help maintain their integrity.

28. Regularly Inspect Screws

Inspect your screws regularly for signs of rust or damage. Discard any screws that are bent, stripped, or corroded. Consequently, you’ll ensure that you always have reliable screws on hand.

Conclusion: The Essential Role of Woodworking Screws

Woodworking screws are indispensable in any woodworker’s toolkit. By understanding the different types, materials, and applications of these fasteners, you can choose the right screw for each project, ensuring strength, durability, and a professional finish. Remember to pre-drill pilot holes, use the correct screw length, and select screws based on the wood type and environment. With these tips in mind, you’ll be well on your way to mastering the art of using woodworking screws.

FAQs about Woodworking Screws

1. What is the best type of screw for outdoor woodworking projects?

The best type of screw for outdoor projects is a corrosion-resistant screw, such as stainless steel or zinc-plated deck screws. These screws are designed to withstand the elements and prevent rust.

2. How do I prevent wood from splitting when using screws?

To prevent wood from splitting, pre-drill pilot holes slightly smaller than the screw’s diameter. Using a countersink bit can also help by allowing the screw head to sit flush with or below the wood surface.

3. What is the difference between wood screws and drywall screws?

Wood screws have a sharp, pointed tip and threads designed for wood, while drywall screws have a bugle-shaped head and are primarily used for securing drywall. However, drywall screws can also be used in woodworking for thin or delicate wood.

4. Can I use brass screws for structural applications?

Brass screws are generally softer than steel or stainless steel screws and are not recommended for structural applications. They are best suited for decorative projects where appearance is a priority.

5. How do I choose the right screw length for my project?

The screw length should be at least twice the thickness of the wood you’re joining. This ensures a strong, secure connection without compromising the integrity of the wood.