When I first ventured into woodworking, I had no idea how essential a router for carpentry would become in my toolkit. It wasn’t just another tool on the shelf; it turned out to be the key to unlocking the kind of detail and precision that separates amateur projects from professional-quality work. I can’t tell you how many times I’ve reached for my router, whether I’m shaping a piece of furniture or adding delicate trim to a cabinet. It’s truly one of the most versatile tools I’ve ever owned, and once you get the hang of it, there’s no turning back.

In this article, I want to take you through everything I’ve learned about using a router for carpentry. From picking the right one to mastering various techniques, this guide is filled with tips and insights based on years of personal experience. Whether you’re just starting out or looking to refine your skills, I hope you’ll find something useful here.

1. Introduction to Routers for Carpentry

So, let me ask you: have you ever worked on a project where the edges weren’t quite perfect, or the joints didn’t line up as seamlessly as you’d hoped? That’s where a router for carpentry can make all the difference. A router is like the Swiss Army knife of woodworking—it can shape, carve, hollow out, and create beautiful details that are almost impossible to achieve with hand tools alone. Once you’ve used one, you’ll wonder how you ever managed without it.

I remember the first time I used a router. It felt a little intimidating at first, but once I got comfortable, it opened up a world of possibilities. Whether you’re building furniture, making cabinets, or just adding some decorative touches to your work, a router is the tool that helps you get that professional finish.

2. The Basics: What Exactly is a Router for Carpentry?

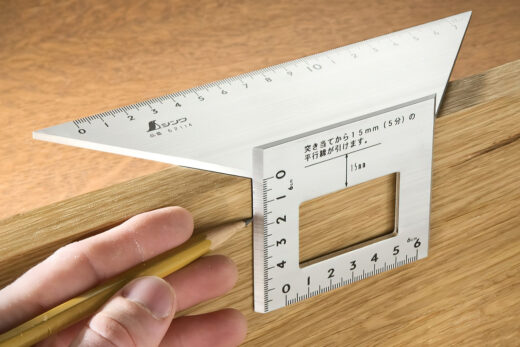

To put it simply, a router for carpentry is a power tool that spins a bit at high speed to cut, shape, or hollow out wood. You can change the bit depending on what kind of cut you need, and there’s a wide variety to choose from. Whether you want to smooth out edges, cut grooves, or add decorative patterns, there’s a bit for every job.

I think of a router as my sculpting tool. It’s the one I reach for when I need precision and detail. Imagine trying to carve intricate edges or hollow out grooves by hand—it would take forever, and the results wouldn’t be nearly as clean. With a router, it’s like having a magic wand that brings your woodworking visions to life.

3. Types of Routers for Carpentry

There are a few different types of routers out there, and choosing the right one depends on the kind of work you plan to do. Here’s a breakdown of the main types I’ve worked with:

Plunge Router for Carpentry

The plunge router is my go-to when I need to start cutting in the middle of a piece of wood. Unlike other routers that require you to start at the edge, a plunge router lets you lower the bit straight into the wood. It’s perfect for making mortises, grooves, or even creating unique designs. When I’m working on a project that requires me to adjust the depth of the cut mid-way, this is the tool I trust.

Fixed-Base Router for Carpentry

I’ve also spent a lot of time using a fixed-base router, especially when I need consistency. With this type of router, the depth of the bit stays fixed, which makes it ideal for edge work or projects where I need the same depth throughout. It’s a bit simpler to use, and if you’re just starting out, I’d recommend getting comfortable with a fixed-base router first. You’ll find it predictable and easier to control.

Trim Router for Carpentry

For those finer, more delicate jobs, I always turn to my trim router. This smaller, more compact tool is perfect for tasks like trimming laminate or adding intricate edges to a project. It’s not as powerful as the larger routers, but what it lacks in size, it makes up for in precision. If you’ve ever worked on detailed trim or finishing, you’ll appreciate how nimble this little router can be.

4. How I Chose My First Router for Carpentry

I remember standing in front of a shelf of routers, completely overwhelmed by the options. If you’re in that boat right now, let me help you out with a few things I’ve learned along the way about picking the right router for carpentry:

Power

The first thing I looked at was power. I wanted something strong enough to handle harder woods, so I went with a router that had at least 2 horsepower (HP). If you’re working with lighter materials, you might not need as much power, but for dense woods, I found that extra oomph really makes a difference.

Variable Speed

The next feature I looked for was variable speed. Not every wood needs the same speed setting, and having the ability to dial it up or down has been incredibly useful. For softer woods, a slower speed works great, while harder woods need a faster rotation to cut cleanly. If you plan to work with a variety of materials like I do, variable speed is a must.

Comfort

Don’t underestimate how important it is for the router to feel good in your hands. You’re going to be holding onto it for long periods, so I made sure to pick one with an ergonomic design. The router should feel balanced and easy to control. I found that having a good grip can mean the difference between a smooth cut and a shaky line.

5. My Favorite Router Bits for Carpentry

Ah, router bits—this is where the magic really happens. Think of router bits as the different brushes in a painter’s toolkit. Each one has a different purpose and helps you achieve a specific effect. Here are the bits I keep on hand and use the most:

Straight Bit

This is the bread and butter of routing. I use a straight bit for cutting grooves, hollowing out areas, and making dados. It’s probably the most versatile bit, and I can’t imagine not having it in my arsenal.

Flush-Trim Bit

When I need to trim the edges of a laminate or make two surfaces perfectly even, the flush-trim bit is my go-to. It’s one of those bits that I didn’t think I’d need until I started working with materials like plywood or laminates, and now I can’t do without it.

Chamfer Bit

If you’re like me and love adding clean, angled edges to your projects, the chamfer bit will be your best friend. I use it all the time to give my work a crisp, professional finish, whether it’s on a tabletop or the edges of a cabinet door.

Round-Over Bit

There’s something about rounded edges that just feels right, isn’t there? I use a round-over bit whenever I want to soften sharp corners on a piece of furniture. It adds a nice, smooth touch that makes everything feel polished and safe—especially important if you have kids running around.

6. Learning Router Techniques: What Worked for Me

One of the things I love about using a router for carpentry is how many techniques you can master over time. When I first started, I was focused on the basics, but as I got more comfortable, I began experimenting with different methods. Here are a few techniques that have become staples in my workshop:

Edge Routing

This was probably the first thing I mastered with my router, and I recommend starting here. Edge routing is when you run the router along the edge of a board to create a decorative profile. It’s a simple technique, but it can transform a plain piece of wood into something elegant and detailed. I use it all the time for tabletops, shelving, and moldings.

Template Routing

If you need to replicate a shape multiple times, template routing is a lifesaver. I’ve used this technique for making identical cabinet doors or shaping furniture legs. All you have to do is create a template of the shape you want, and then use the router to follow the pattern. It’s accurate and saves you a ton of time.

Joinery

One of the reasons I fell in love with my router was because of how easy it makes joinery. Whether I’m making dovetails, dadoes, or rabbets, the router gives me the precision I need to create tight, professional-looking joints. No more wobbly drawer boxes or uneven shelves!

7. Why I Believe Every Workshop Needs a Router for Carpentry

If there’s one tool I can’t live without, it’s my router for carpentry. The versatility it offers is unmatched. It’s not just about cutting wood; it’s about opening up creative possibilities. From simple edge profiling to complex joinery, there’s so much you can do with a router that it feels like an extension of my hands. I honestly believe that every woodworker, whether a beginner or a pro, should invest in a router—it’ll change the way you approach your projects.

8. Router Safety: What I Do to Stay Safe

I’ll admit, when I first started using a router, the speed and power of the tool were a little intimidating. Over time, I’ve developed a few safety habits that keep me safe while using my router, and I’d love to share them with you:

- Protective Gear: I never start a routing project without my safety glasses and ear protection. Routers can throw up a lot of sawdust, and the noise can be deafening after a while.

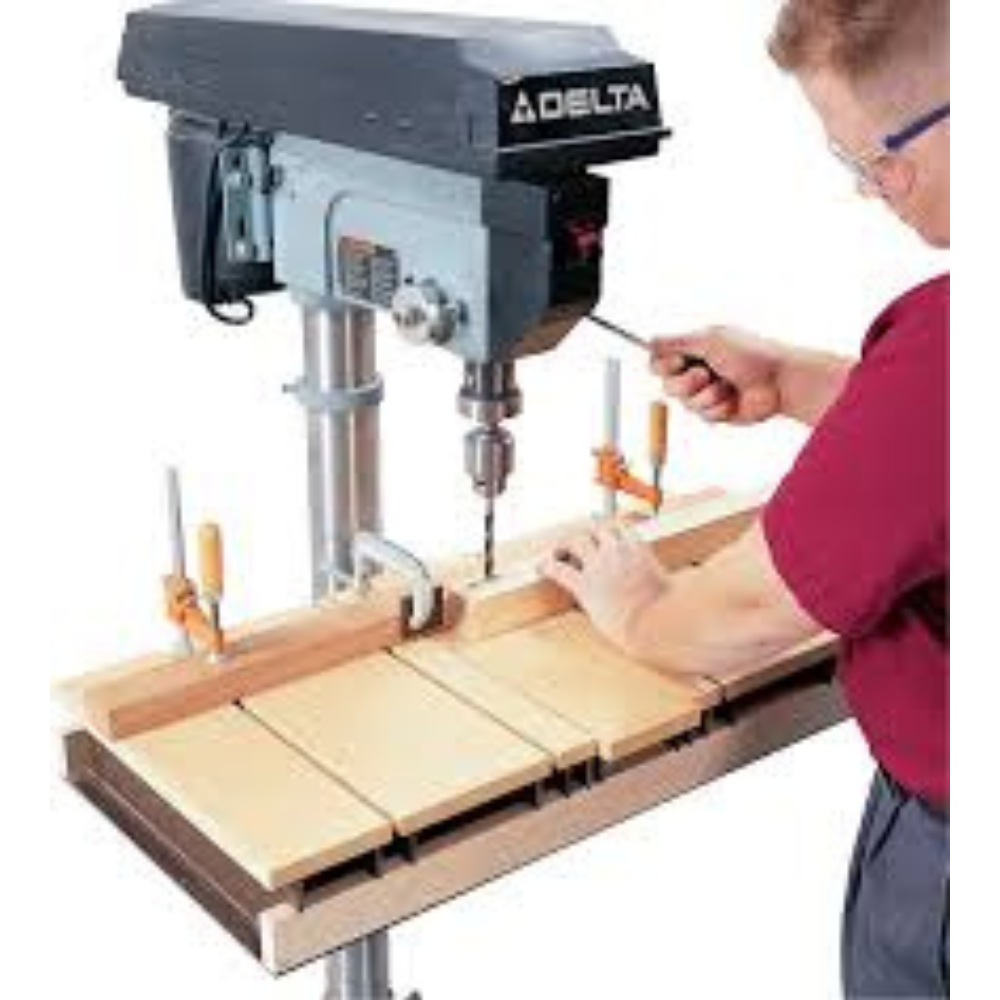

- Keep Hands Clear: This might sound obvious, but always keep your hands away from the spinning bit. I’ve found that using push blocks and jigs helps keep my hands out of harm’s way.

- Go Slow: One mistake I made early on was trying to rush through a cut. Big mistake! Going slow and steady not only gives you a cleaner cut but also reduces the chances of accidents.

Conclusion: Why the Router is My Carpentry MVP

In all my years of woodworking, the router for carpentry has remained my most trusted and versatile tool. It’s helped me create beautiful, professional-grade work that I’m proud to show off. Whether you’re just getting started or looking to take your skills to the next level, I can’t recommend investing in a router enough. It’s a tool that truly grows with you, and the more you use it, the more possibilities you’ll uncover.

So go ahead—grab a router, experiment, and see where it takes you. I guarantee it’ll become one of your favorite tools in no time.

FAQs About Router for Carpentry

1. How do I prevent tear-out when using a router for carpentry? Preventing tear-out is all about grain direction. Always route with the grain, and if you’re working on end grain, take shallow passes. Using a sharp bit helps too!

2. What’s the best type of wood to use with a router? Most woods work well with a router, but hardwoods like oak and maple tend to give cleaner cuts. Softer woods can sometimes splinter, so I recommend using sharp bits and slower speeds when working with pine or poplar.

3. Can I use a router for carpentry on MDF or plywood? Absolutely! I often use a router on MDF and plywood, especially for cabinetry. Just be sure to use the right bits and speeds to avoid chipping or tear-out.

4. Should I get a plunge router or a fixed-base router? Both are great, but if you’re just starting out, I’d recommend a fixed-base router. It’s easier to control, and you can always add a plunge base later once you’re more comfortable.

5. How do I know when it’s time to replace my router bits? You’ll know it’s time when your cuts start to look rough or you feel more resistance during routing. Dull bits strain your router and can leave burn marks on your wood. Keep an eye on the quality of your cuts!