Woodworking hand planes are one of the most essential tools in a woodworker’s arsenal, making woodworking a timeless craft. Whether you’re a seasoned woodworker or a beginner, understanding the various types of hand planes and their uses can significantly enhance your craftsmanship. This comprehensive guide will delve into everything you need to know about woodworking hand planes, ensuring you’re well-equipped to tackle any project with confidence.

For your “Free” Guide to 13 Wood Joinery Types – Click Here.

Introduction to Woodworking Hand Planes

Hand planes have been around for centuries, helping woodworkers achieve smooth, flat surfaces on their projects. These tools come in various shapes and sizes, each designed for specific tasks. By mastering the use of woodworking hand planes, you can achieve a level of precision and quality that power tools often can’t match.

The History of Hand Planes

Hand planes have a rich history, dating back to ancient civilizations. The earliest versions were simple tools made from stone and wood. Over time, they evolved into the sophisticated metal and wooden planes we use today. Understanding their history gives us a greater appreciation for their role in woodworking. The Egyptians, Romans, and medieval craftsmen all contributed to the development of hand planes. Each culture improved upon the design and functionality, leading to the diverse range of planes available today.

Types of Woodworking Hand Planes

There are several types of hand planes, each serving a unique purpose. Let’s explore some of the most common ones:

- Block Plane

- Bench Plane

- Shoulder Plane

- Router Plane

- Rabbet Plane

- Scrub Plane

- Joinery Plane

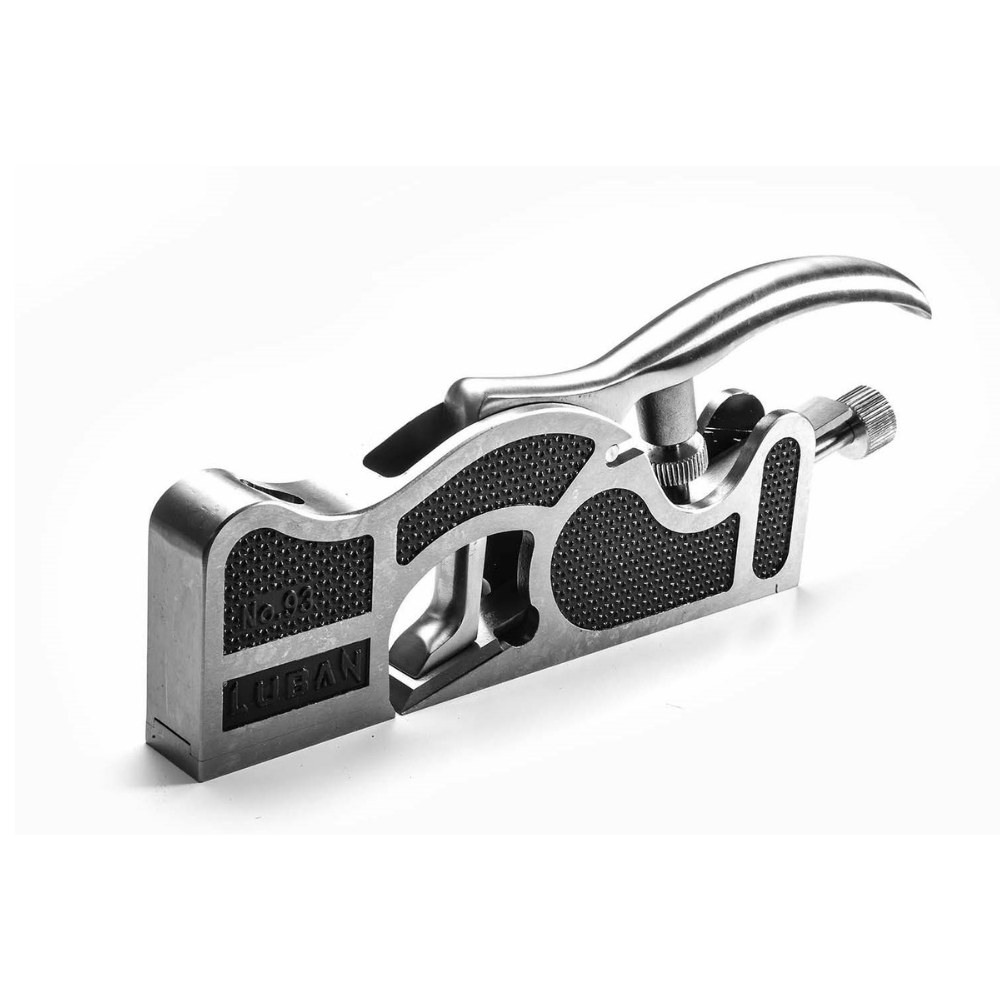

The Essential Block Plane

The block plane is a small, versatile tool perfect for trimming and fine-tuning. It’s easy to handle and is ideal for tasks that require precision, such as fitting joints or smoothing edges. Block planes typically have their blades set at a lower angle compared to other planes, making them excellent for end grain work. They come in standard and low-angle versions, each suited for different tasks. The compact size of block planes makes them easy to carry and use, even in tight spaces.

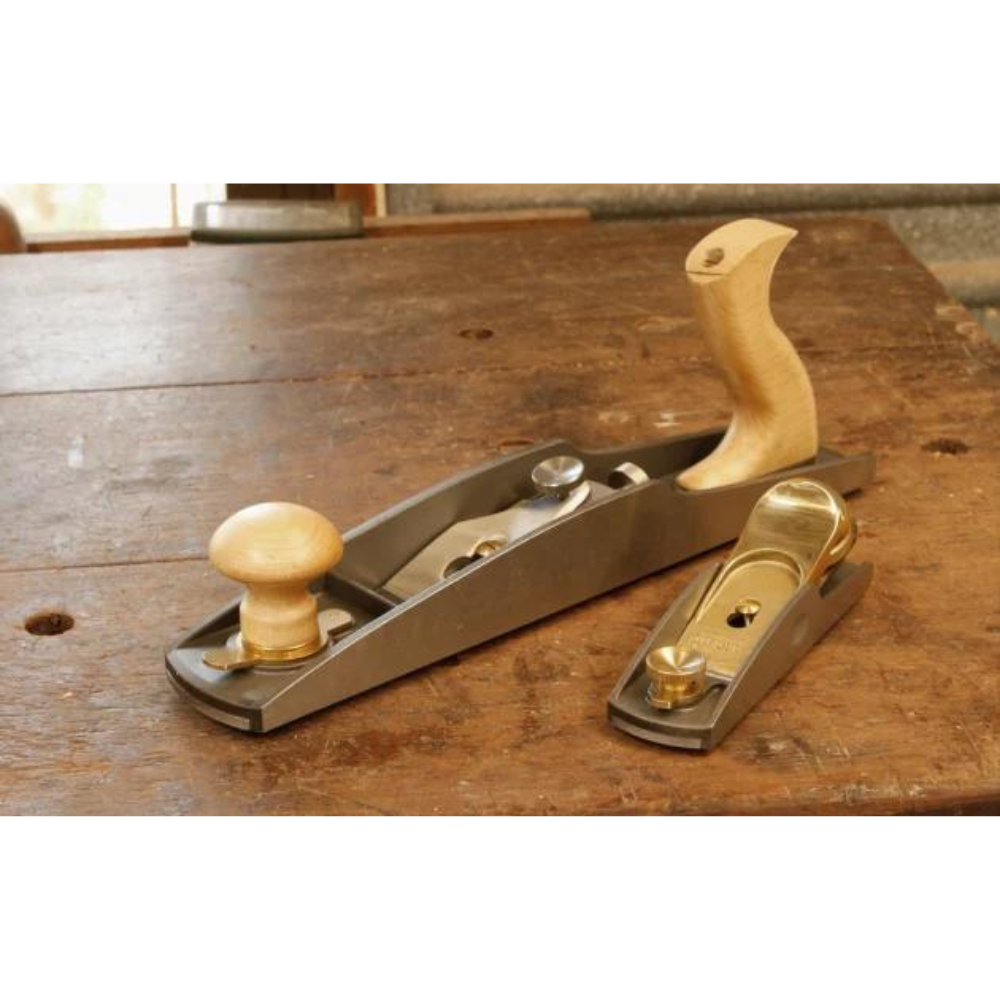

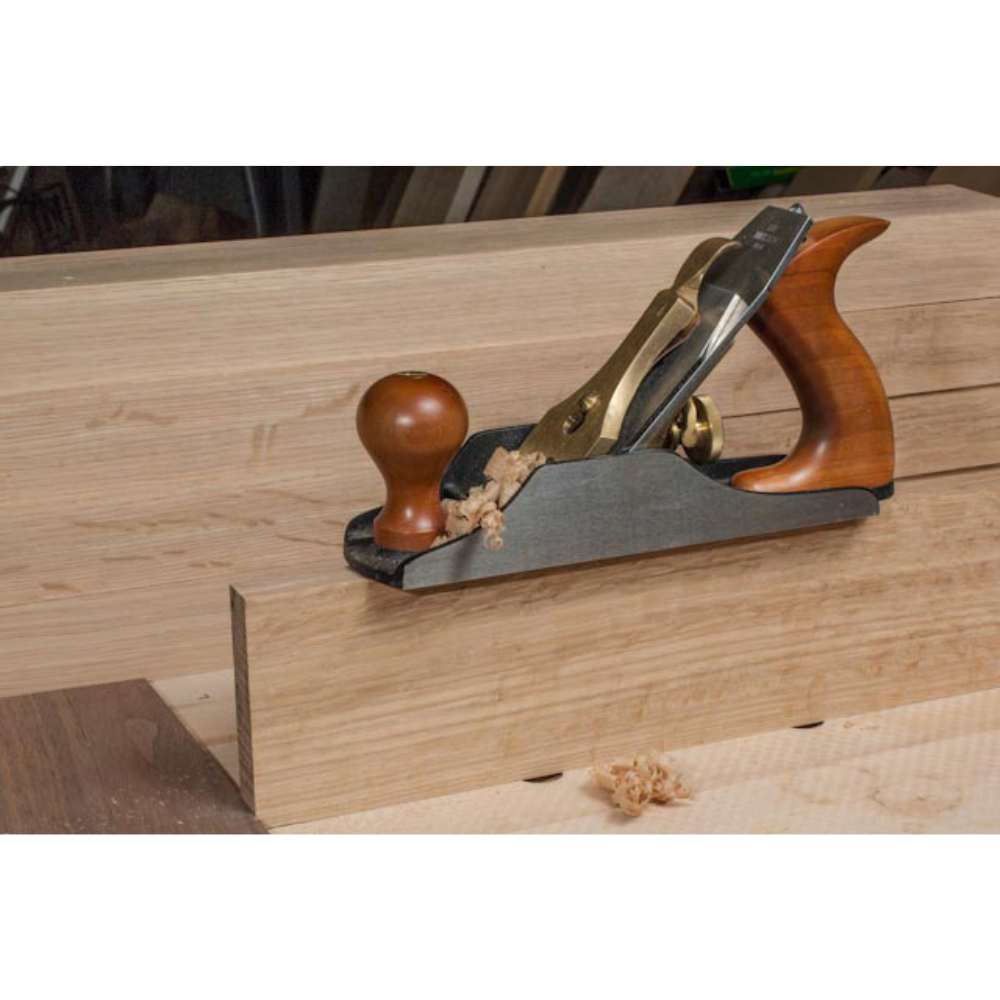

Bench Planes: The Workhorses

Bench planes are larger and more robust, making them perfect for flattening and smoothing large surfaces. They come in various sizes, with the number indicating the plane’s length. Common bench planes include the No. 4 smoothing plane, the No. 5 jack plane, and the No. 7 jointer plane. Each type of bench plane serves a specific purpose:

- Smoothing Plane (No. 4): Ideal for final smoothing before finishing.

- Jack Plane (No. 5): A versatile plane used for rough work and initial flattening.

- Jointer Plane (No. 7): Perfect for jointing edges and flattening large surfaces.

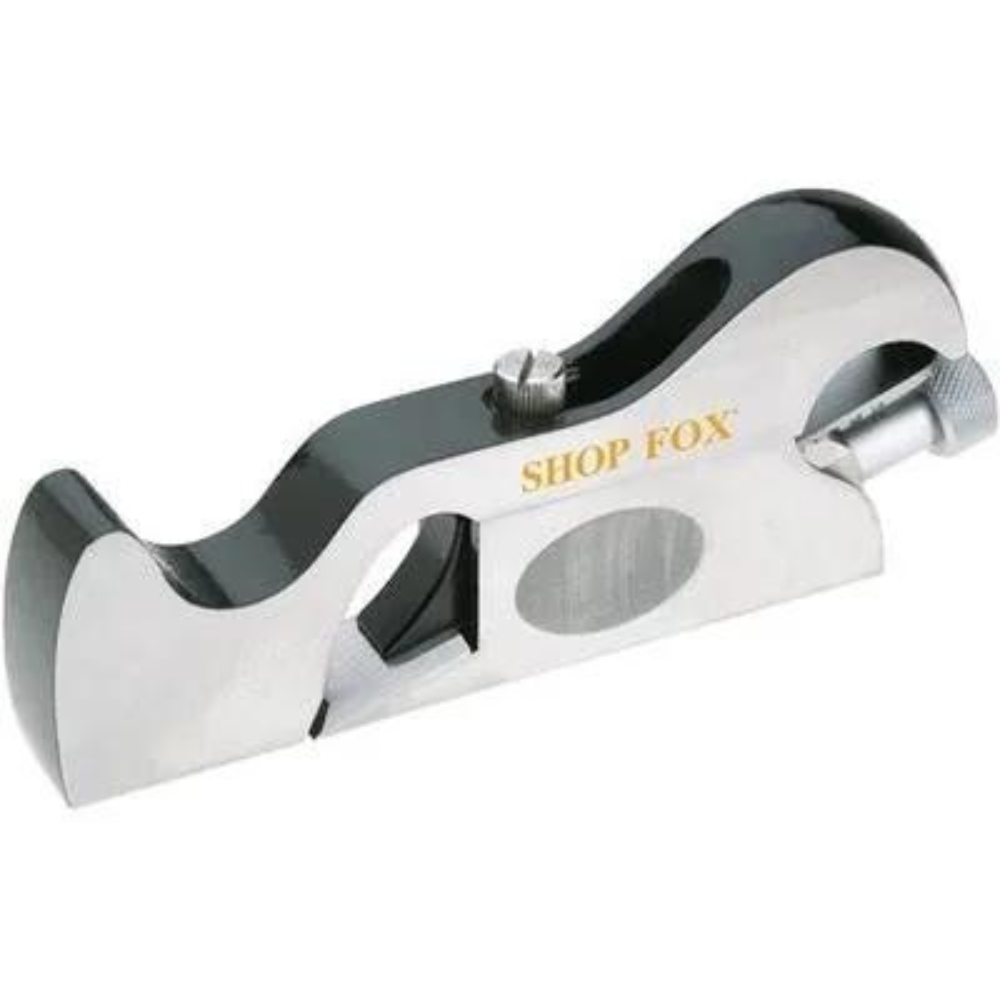

Shoulder Planes for Precision Work

Shoulder planes are designed for trimming tenons and other joinery. Their narrow bodies allow them to fit into tight spaces, making them indispensable for detailed work. The blade extends the full width of the tool, allowing you to cut right up to the edge of a workpiece. This makes shoulder planes perfect for fine-tuning the fit of joints and ensuring a clean, precise finish.

Router Planes for Consistency

Router planes are used to create consistent, precise grooves and recesses. They are perfect for tasks like creating dados or inlays. The blade of a router plane is mounted vertically and can be adjusted to different depths, providing control over the cut. Router planes are often used in conjunction with templates or guides to achieve accurate, repeatable results.

Rabbet Planes for Specialized Cuts

Rabbet planes are designed for cutting rabbets (or rebates), which are recesses along the edge of a piece of wood. They are essential for joinery and can also be used to create decorative elements. Rabbet planes feature a blade that extends to the edge of the plane body, allowing you to cut right up to a shoulder or corner. They can be adjusted to cut different widths and depths, making them versatile tools for various woodworking tasks.

Scrub Planes for Heavy Stock Removal

Scrub planes are designed for quick, aggressive stock removal. They are used to rough out shapes and prepare rough-sawn lumber for further refinement. Scrub planes have a heavily cambered blade, which allows them to take thick shavings and quickly reduce the thickness of a workpiece. They are particularly useful for initial flattening of rough stock and preparing boards for planing with finer tools.

Joinery Planes for Fine Work

Joinery planes, such as plow planes and shoulder planes, are used for precise joinery work. These planes are designed for creating grooves, dados, and other detailed cuts that require accuracy and precision. Plow planes are adjustable and come with various cutters, allowing you to create different widths and depths of grooves. Joinery planes are essential for tasks like fitting joints, creating moldings, and adding decorative details to your workpieces.

Choosing the Right-Hand Plane

Selecting the right hand plane depends on the task at hand. For general smoothing and flattening, a bench plane is your best bet. For detailed work, a block or shoulder plane is ideal. Understanding the strengths of each type will help you choose the right tool for your project. Consider factors such as the size of the workpiece, the type of wood, and the desired finish when selecting a hand plane. Investing in a quality hand plane will pay off in the long run, as a well-made tool will provide better results and last longer.

Maintaining Your Hand Planes

Proper maintenance is crucial for keeping your hand planes in top condition. This includes regular sharpening, cleaning, and storing them correctly. A well-maintained hand plane can last a lifetime and provide years of reliable service. Regular maintenance not only ensures optimal performance but also prevents damage to the tool and extends its lifespan. Here are some tips for maintaining your hand planes:

- Cleaning: After each use, clean your hand plane to remove any wood shavings, dust, and debris. Use a brush or compressed air to clean hard-to-reach areas. Wipe down the plane with a soft cloth to remove any moisture and prevent rust.

- Sharpening: A sharp blade is essential for achieving clean, smooth cuts. There are various methods for sharpening hand plane blades, including using sharpening stones, honing guides, and power sharpeners. Regular sharpening will keep your planes performing at their best.

- Lubrication: Apply a light coat of oil or wax to the metal parts of your hand plane to prevent rust and ensure smooth operation. This is especially important for planes that are used infrequently or stored in humid environments.

- Storage: Store your hand planes in a dry, cool place to prevent rust and damage. Keep them in a protective case or tool chest to prevent dust and debris from accumulating. Avoid storing hand planes on their blades to prevent damage to the cutting edge.

For your “Free” Workspace Plans – Click Here.

Sharpening Your Hand Planes

A sharp blade is essential for achieving clean, smooth cuts. There are various methods for sharpening hand plane blades, including using sharpening stones, honing guides, and power sharpeners. Regular sharpening will keep your planes performing at their best. Here are some tips for sharpening your hand plane blades:

- Sharpening Stones: Use sharpening stones to maintain a sharp edge on your hand plane blades. Start with a coarse grit stone to remove any nicks or damage, then progress to finer grit stones for a razor-sharp edge. Water stones, oil stones, and diamond stones are popular choices for sharpening hand plane blades.

- Honing Guides: A honing guide helps maintain a consistent angle while sharpening your blade. This ensures an even, sharp edge and reduces the risk of damaging the blade. Honing guides are available in various styles and can be adjusted to accommodate different blade widths and angles.

- Stropping: After sharpening, use a leather strop to remove any burrs and polish the edge of the blade. Stropping helps achieve a mirror-like finish and ensures a razor-sharp cutting edge. Apply a small amount of honing compound to the strop for optimal results.

Tuning Your Hand Planes

Tuning your hand planes involves adjusting them for optimal performance. This includes setting the blade depth, aligning the blade, and ensuring the sole is flat. Proper tuning will enhance the accuracy and ease of use of your hand planes. Here are some steps for tuning your hand planes:

- Blade Depth: Adjust the blade depth to control the thickness of the shavings. A shallow blade setting produces thin shavings for fine smoothing, while a deeper setting removes more material for rough shaping. Use the depth adjustment knob to set the blade to the desired depth.

- Blade Alignment: Ensure the blade is parallel to the sole of the plane for even cutting. Use the lateral adjustment lever to align the blade if necessary. A misaligned blade can cause uneven cuts and reduce the quality of your work.

- Sole Flatness: Check the sole of the plane for flatness using a straightedge. A flat sole ensures consistent contact with the workpiece and prevents the plane from rocking or digging into the wood. If the sole is not flat, use a flat surface and sandpaper to flatten it.

Using Woodworking Hand Planes Safely

Safety is paramount when using hand planes. Always wear protective gear, such as safety glasses, and use proper technique to avoid injuries. Keep your work area clean and free of obstacles to ensure a safe working environment. Here are some safety tips for using hand planes:

- Proper Technique: Use smooth, controlled strokes when planning to prevent accidents and ensure accurate results. Avoid applying excessive force, as this can cause the plane to slip or dig into the wood. Maintain a firm grip on the plane and keep your hands away from the blade.

- Sharp Blades: Keep your blades sharp to reduce the risk of accidents and improve cutting performance. Dull blades require more force and are more likely to slip, increasing the risk of injury. Regularly inspect and sharpen your blades to maintain optimal performance.

- Protective Gear: Wear safety glasses to protect your eyes from flying debris and dust. Consider wearing hearing protection if you are working in a noisy environment or using power tools in conjunction with hand planes. Use gloves to protect your hands from sharp edges and splinters.

Common Mistakes to Avoid

Even experienced woodworkers can make mistakes when using hand planes. Common errors include using a dull blade, applying too much pressure, or failing to maintain the tool properly. Avoiding these mistakes will improve your results and extend the life of your hand planes. Here are some common mistakes to watch out for:

- Dull Blades: Using a dull blade can result in tear-out, uneven cuts, and a rough finish. Regularly sharpen your blades to ensure clean, smooth cuts and reduce the risk of damage to your workpiece.

- Excessive Pressure: Applying too much pressure can cause the plane to dig into the wood, resulting in uneven cuts and gouges. Use smooth, controlled strokes and let the sharp blade do the work.

- Improper Maintenance: Neglecting to clean, sharpen, and tune your hand planes can lead to poor performance and damage to the tool. Regular maintenance is essential for keeping your hand planes in top condition and ensuring optimal results.

Advanced Techniques with Hand Planes

Once you’ve mastered the basics, you can explore advanced techniques with hand planes. This includes creating custom profiles, using jigs and guides, and incorporating hand planes into complex joinery. These techniques will elevate your woodworking skills to new heights. Here are some advanced techniques to try:

- Custom Profiles: Use molding planes or profile cutters to create custom profiles and decorative details. This allows you to add unique elements to your projects and showcase your creativity and skill.

- Jigs and Guides: Use jigs and guides to achieve precise, repeatable results. Jigs can help you maintain consistent angles and depths, while guides ensure straight, accurate cuts. Experiment with different jigs and guides to expand your capabilities and improve your results.

- Complex Joinery: Incorporate hand planes into complex joinery tasks, such as dovetail joints, mortise and tenon joints, and finger joints. Hand planes can help you achieve tight, precise fits and smooth, clean surfaces for your joints.

The Joy of Woodworking with Hand Planes

There’s something deeply satisfying about working with hand planes. The tactile feedback, the sound of the blade slicing through wood, and the smooth finish they leave behind make woodworking a truly rewarding experience. Hand planes allow you to connect with your work on a deeper level. Here are some reasons to embrace hand plane woodworking:

- Craftsmanship: Hand planes offer a level of precision and control that power tools often can’t match. Using hand planes allows you to achieve a higher level of craftsmanship and create workpieces with a personal touch.

- Simplicity: Hand planes are simple tools that require no electricity or complex setups. This makes them accessible and easy to use, even for beginners. The simplicity of hand planes allows you to focus on your technique and the quality of your work.

- Satisfaction: The process of planing wood by hand is meditative and satisfying. The rhythmic motion, the feel of the wood, and the visible progress make woodworking with hand planes a fulfilling experience.

Building Your Hand Plane Collection

As you become more experienced, you may want to expand your collection of hand planes. Each new plane opens up new possibilities and allows you to tackle a wider range of projects. Collecting hand planes can be a lifelong journey, filled with discovery and growth. Here are some tips for building your hand plane collection:

- Start Small: Begin with a few essential planes, such as a block plane, a smoothing plane, and a jack plane. These versatile tools will cover a wide range of tasks and provide a solid foundation for your collection.

- Quality Over Quantity: Invest in high-quality hand planes that are well-made and built to last. Quality tools will provide better results and be more enjoyable to use. Look for reputable brands and consider purchasing vintage planes that can be restored.

- Expand Gradually: Add new planes to your collection as you encounter specific needs and challenges in your woodworking projects. Each new plane should address a specific task or improve your capabilities. Over time, your collection will grow to include a diverse range of tools.

For your “Free” Guide to 13 Wood Joinery Types – Click Here.

Conclusion

Woodworking hand planes are indispensable tools for any woodworker. By understanding their history, types, and uses, you can enhance your craftsmanship and achieve professional-quality results. Whether you’re just starting or looking to refine your skills, mastering the use of hand planes will take your woodworking to the next level. Investing time in learning about and using woodworking hand planes will not only improve your skills but also deepen your appreciation for the art of woodworking.

FAQs About Woodworking Hand Planes

1. What is the best hand plane for beginners? The best hand plane for beginners is usually a block plane. It’s versatile, easy to handle, and perfect for a variety of tasks.

2. How often should I sharpen my hand plane blades? It depends on how frequently you use them. Generally, it’s good practice to sharpen your blades after every few hours of use to maintain optimal performance.

3. Can I use hand planes on all types of wood? Yes, hand planes can be used on most types of wood. However, some harder woods may require more frequent sharpening and tuning.

4. What should I do if my hand plane isn’t cutting smoothly? If your hand plane isn’t cutting smoothly, check the blade sharpness, adjust the blade depth, and ensure the sole is flat. Proper tuning and maintenance are key.

5. Are there any alternatives to hand planes for smoothing wood? While power tools like electric planers and sanders can be used, hand planes offer a level of precision and control that’s hard to match. They are also quieter and don’t require electricity.

By investing time in learning about and using woodworking hand planes, you’ll not only improve your skills but also gain a deeper appreciation for the art of woodworking. So, pick up a hand plane, and let the shavings fly!