Woodworking is an ancient craft, and every woodworker, novice or pro, must master the art of joining wood. This is where woodworking fasteners come in. They might seem like minor details, but choosing the right fastener can mean the difference between a well-built, durable piece and a frustrating failure. In this guide, we’ll dive deep into the world of woodworking fasteners, offering essential advice on types, uses, and tips for choosing the best one for your projects.

1. What Are Woodworking Fasteners?

Woodworking fasteners are tools used to join pieces of wood together. They range from simple nails to advanced bolts, helping woodworkers create solid structures or decorative accents. Understanding their uses and differences is crucial to achieving high-quality results.

Fasteners are often selected based on project requirements and wood types, considering factors like weight-bearing capacity and appearance. Some fasteners are visible, while others remain hidden, giving the piece a clean, unobtrusive look.

2. Nails: The Classic Woodworking Fasteners

Nails are perhaps the oldest form of woodworking fasteners. They’re available in various sizes, shapes, and materials to cater to different wood types and applications. Choosing the right nail is essential to avoid wood splitting or insufficient holding power.

Some popular types of nails include:

- Common Nails: These have thick shanks and are ideal for framing or rough carpentry.

- Finish Nails: Thinner and less visible, used for interior trim or finishing work.

- Box Nails: With a thinner shank, these nails reduce the risk of splitting wood but offer less holding power.

- Duplex Nails: Easily removable, they’re used for temporary constructions like scaffolding.

When working with nails, the length should generally be at least three times the thickness of the wood being joined. Too short, and it won’t hold; too long, and it risks splitting the wood.

3. Screws: A Stronger Alternative in Woodworking Fasteners

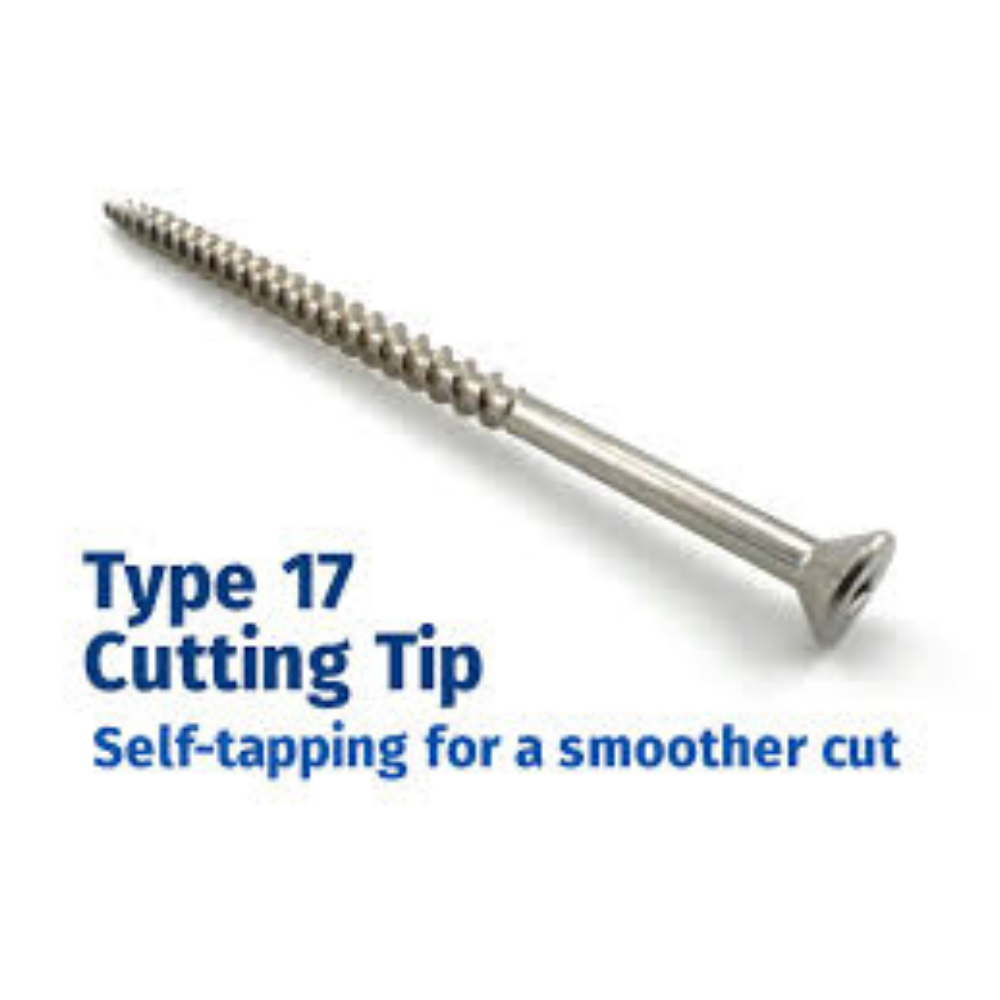

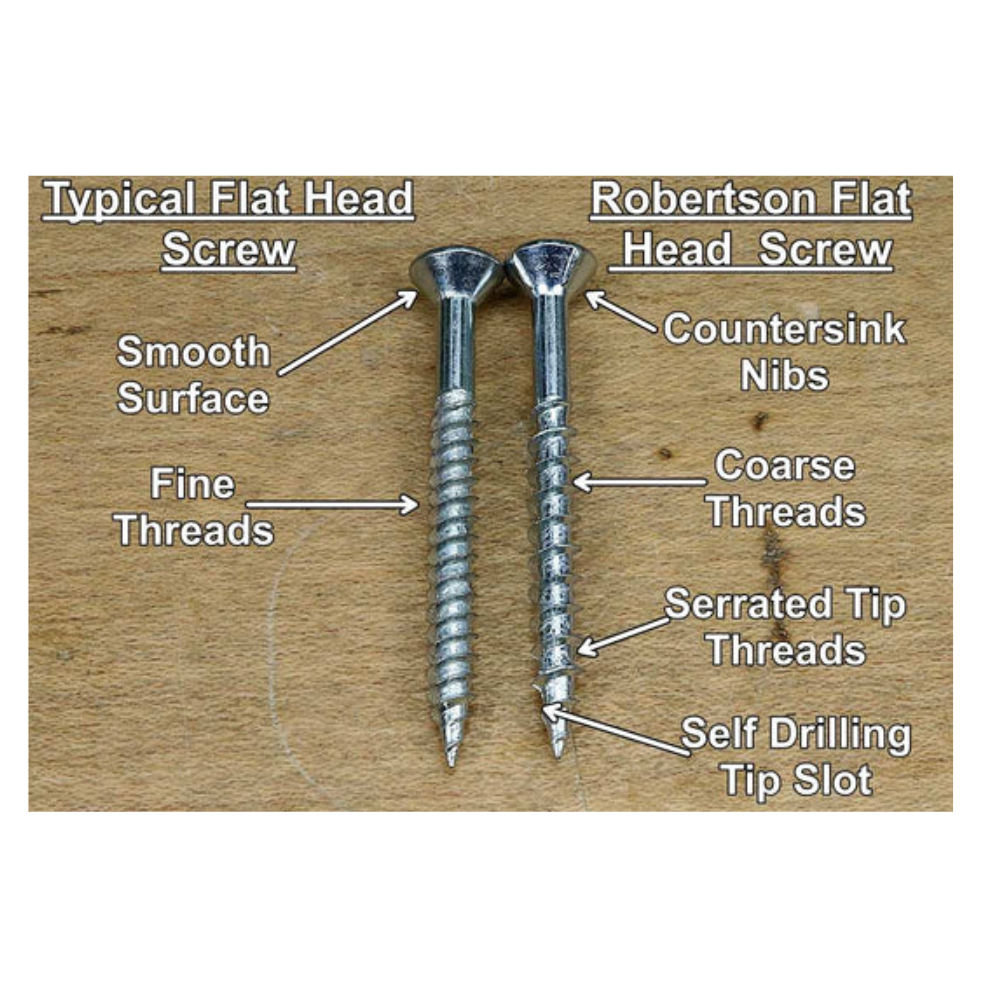

Screws provide a stronger hold than nails and are versatile woodworking fasteners. They come in a dizzying array of sizes, head types, and thread patterns. Most importantly, screws can be removed and reused, making them suitable for furniture projects that may need future adjustments.

Some common types include:

- Wood Screws: Designed explicitly for woodworking, they come in various head styles like flat, round, or oval.

- Drywall Screws: Thin but with deep threads, they are often used for lightweight woodworking projects.

- Deck Screws: Weather-resistant and suitable for outdoor projects, especially decks.

- Lag Screws: Heavy-duty and excellent for large projects like fences or structural work.

When selecting screws, consider their material and coating. Stainless steel or coated screws are better for outdoor projects due to their resistance to rust. For a clean finish, countersink the screw and cover it with wood putty or a wood plug.

4. Bolts and Nuts: For Heavy-Duty Fastening

Bolts and nuts are ideal for applications requiring high clamping force or where joints may be under significant stress. Carriage bolts, lag bolts, and machine bolts each have unique properties suited for different woodworking projects.

- Carriage Bolts: These have a round head and a square section under the head that locks into the wood to prevent rotation.

- Lag Bolts: Similar to screws but much thicker, often used in heavy timber construction.

- Machine Bolts: Paired with nuts to create a secure and tight connection.

Bolts usually require pre-drilled holes, and washers can help distribute the load over a larger surface, preventing the bolt from pulling through the wood.

5. Dowels: Invisible Strength in Woodworking Fasteners

Dowels are a clever solution for those seeking nearly invisible woodworking fasteners. They are inserted into drilled holes and glued, creating hidden yet secure joints often used in furniture assembly.

Dowels offer excellent holding strength when glued correctly, and the alignment of holes is crucial for a perfect fit. Doweling jigs can help align holes precisely. Dowels work exceptionally well for edge-to-edge joints and where a seamless appearance is desired.

6. Biscuits and Biscuit Joints

Biscuit joints involve oval-shaped wooden biscuits inserted into slots made by a special tool. The biscuits swell with glue, creating a tight and strong joint, especially popular for edge-to-edge joining like tabletops.

Biscuit joints offer quick assembly and ensure perfect alignment. However, they’re not ideal for joints bearing high stress or load. The key to success is using the correct biscuit size for the wood’s thickness.

7. Pocket Hole Screws

Pocket hole screws are specifically designed for pocket hole joinery, creating angled joints by driving screws into pre-drilled holes at a shallow angle. This technique is often used for hidden, strong connections in cabinetry.

Pocket hole jigs make it easy to create accurate pocket holes consistently. The special screws have wide heads that firmly grip the pocket’s surface, securing the joint tightly. Pocket hole joinery is versatile, offering strong joints with minimal visible hardware.

For your “Free” Guide to 13 Wood Joinery Types – Click Here.

8. Brads and Brad Nails: Delicate and Discreet

Brads are thinner than traditional nails, making them suitable for more delicate woodworking projects like trim and molding. They provide secure fastening without damaging the material’s surface.

Brad nails are usually driven using a pneumatic or electric brad nailer, ensuring precise, rapid, and almost invisible fastening. They’re perfect for moldings, picture frames, and small cabinetry details where holding power is crucial without marring the wood.

9. Staples: Quick and Efficient Fasteners

Staples are ideal for quick fastening, particularly in upholstery or where multiple layers of wood or other materials are involved. They might not be suitable for structural joints, but they’re indispensable for specific applications.

Staple guns (manual, electric, or pneumatic) make quick work of fastening wood veneers, fabric, or wiring to wooden frames. They’re also commonly used in cabinet backs, drawer bottoms, and other lightweight applications.

10. Rivets in Woodworking Fasteners

Though primarily used in metalworking, rivets find their way into woodworking for their secure fastening properties. They are especially useful in mixed-material projects where both wood and metal need to be connected.

Blind rivets, or pop rivets, are the most common type used in woodworking because they can be installed from one side. Riveting requires specialized tools, but the result is a tight, long-lasting connection that can withstand vibrations.

11. Glues as Woodworking Fasteners

Though not technically fasteners, adhesives are crucial to woodworkers. Wood glues like PVA, epoxy, and cyanoacrylate act as powerful bonding agents, sometimes stronger than nails or screws, depending on the application.

- PVA Glue: A staple in most shops, PVA glue (also known as carpenter’s glue) is perfect for general-purpose joinery and can be sanded or painted once dry.

- Epoxy: Excellent for filling gaps and offering superior strength. Ideal for repairing damaged wood.

- Cyanoacrylate (CA): Also known as super glue, it’s best used for small repairs or temporarily holding pieces before permanent fastening.

Proper glue application is crucial. Apply evenly across both surfaces, clamp firmly, and allow ample drying time to achieve optimal strength.

12. Selecting the Right Fastener for Your Project

Choosing the right woodworking fastener depends on several factors, including the type of wood, stress loads, and project requirements. Delicate projects may require brads or dowels, while heavy-duty builds may need bolts or screws.

Consider the following factors:

- Wood Species: Hardwoods may require pre-drilling to prevent splitting, while softwoods are more forgiving.

- Load Requirements: How much weight will the joint bear? Screws or bolts are often better for high-load applications.

- Environmental Conditions: Outdoor projects demand fasteners that can resist corrosion.

A thorough assessment ensures that your chosen fastener will deliver both function and aesthetic appeal.

13. Pre-Drilling: The Unsung Hero

Pre-drilling can save your wood from splitting and give screws better grip. It’s a step that many woodworkers skip but can significantly improve joint strength.

The drill bit size should be slightly smaller than the screw’s core diameter, ensuring the screw threads will bite into the surrounding wood while preventing splitting. Countersinking is equally important when working with hardwoods, providing a smooth surface for screws.

14. Common Mistakes to Avoid with Fasteners

Using the wrong fastener or not accounting for wood movement can cause catastrophic failure. Avoid driving screws too close to the edge or using nails that are too long, as both can weaken your joints.

Other common mistakes include:

- Overdriving Screws: This can strip the threads or weaken the surrounding wood.

- Wrong Fastener Size: Fasteners that are too small won’t hold, while those too large can damage the joint.

- Ignoring Wood Movement: Some fasteners restrict wood movement, leading to cracking.

When in doubt, test on scrap wood before applying the fastener to your final piece.

15. Finishing Touches: Making Fasteners Invisible

Counter-sinking, wood fillers, and plugs can help conceal woodworking fasteners for a clean, professional look. These techniques are often used in fine furniture making to hide screws and nails.

- Countersinking: Creates a small hole to bury the fastener head below the surface.

- Wood Filler: Matches the surrounding wood to cover nail or screw heads.

- Plugs: Use dowels or pre-made wood plugs to cover countersunk screw holes.

Taking the time to hide fasteners can elevate a project from amateur to artisan.

16. Creative Fastening Solutions

Mixing fastener types or using a combination of mechanical and adhesive fasteners can lead to innovative joinery solutions. Experimenting with different types can yield results that are both strong and aesthetically pleasing.

For instance, a combination of dowels and screws can offer a tight, hidden joint for furniture. Alternatively, using rivets and bolts in tandem can create attractive accents that blend metal and wood seamlessly.

17. Why Practice Matters in Fastening Techniques

Woodworking fasteners are only as effective as the skill with which they are applied. Practicing different joinery techniques is vital for mastering the art of fastening, ensuring that each piece you make stands the test of time.

Consider setting up a small test project where you can try out different fasteners, learn their strengths and limitations, and see how they impact various wood types. Practical experimentation will also reveal which techniques you feel most confident using.

18. Conclusion: Craftsmanship and Fasteners Go Hand in Hand

Woodworking fasteners are indispensable to the craft. Whether you’re using traditional nails or innovative biscuits, understanding each type’s strengths and weaknesses is essential for creating long-lasting, beautiful wood projects. Next time you’re planning a woodworking project, take a moment to choose the best fastener for the job – it’s often the key to perfect joinery.

For your “Free” Workspace Plans – Click Here.

Frequently Asked Questions About Woodworking Fasteners

- What is the strongest woodworking fastener?

The strongest woodworking fastener varies by application. For heavy-duty projects, bolts and nuts are ideal due to their clamping power. Screws also offer significant strength when correctly applied, especially for wood-to-wood connections. - Should I use nails or screws for my woodworking project?

It depends on the project’s requirements. Nails are faster to install and useful for trim and framing, while screws provide a stronger hold and are better for projects needing future adjustments or where additional strength is essential. - How do I prevent wood from splitting when using fasteners?

Pre-drilling is key to preventing wood from splitting, especially when using screws or nails near edges. Selecting the appropriate size and type of fastener and driving it at a moderate speed also helps reduce the risk of splits. - Can I mix different fasteners in one project?

Yes! Mixing fasteners can offer creative and practical solutions. For instance, combining mechanical fasteners like screws with adhesives or dowels can enhance the joint’s strength while providing aesthetic advantages. - Are wood glues strong enough to replace mechanical fasteners?

Wood glues can be stronger than mechanical fasteners in specific applications, particularly when joining edge-to-edge. However, using glues in combination with screws or nails often leads to a more durable and reliable bond.