Introduction to Balsa Woodworking

Balsa woodworking is a fascinating and accessible craft, perfect for anyone looking to explore the world of woodworking without the heavy equipment typically required. This unique material, known for its lightweight and soft characteristics, offers a wide range of possibilities for both novices and experienced woodworkers. Whether you’re building models, creating decorative items, or experimenting with new woodworking techniques, balsa wood is an excellent material to work with.

What is Balsa Wood?

Balsa wood comes from the Ochroma pyramidale tree, found primarily in South and Central America. It is the lightest commercial wood available, making it incredibly popular in industries ranging from model building to insulation due to its buoyancy and soundproofing qualities.

Benefits of Working with Balsa Wood

Working with balsa wood offers several advantages that make it a preferred choice for many projects:

- Lightweight: Its lightweight nature makes it ideal for model aircraft and small craft projects.

- Easy to Handle: The softness of balsa allows for easy cutting and shaping.

- Absorptive: Balsa’s high absorbency makes it excellent for various finishes and glues.

Types of Balsa Wood Products

Balsa wood is available in several forms, each suited for different applications:

- Sheets: These are commonly used in model building, where precise, flat pieces are needed.

- Blocks: Perfect for carving and turning on lathes.

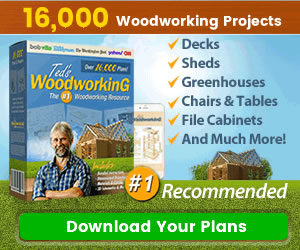

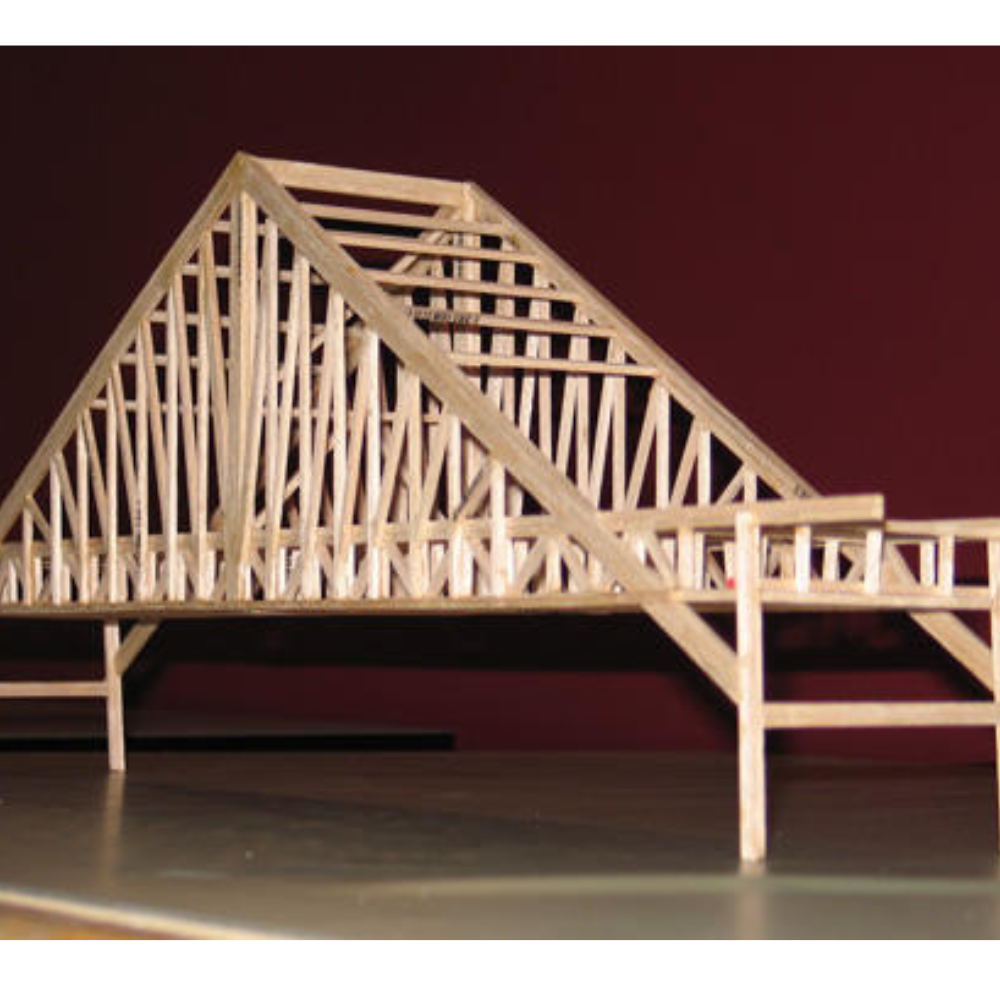

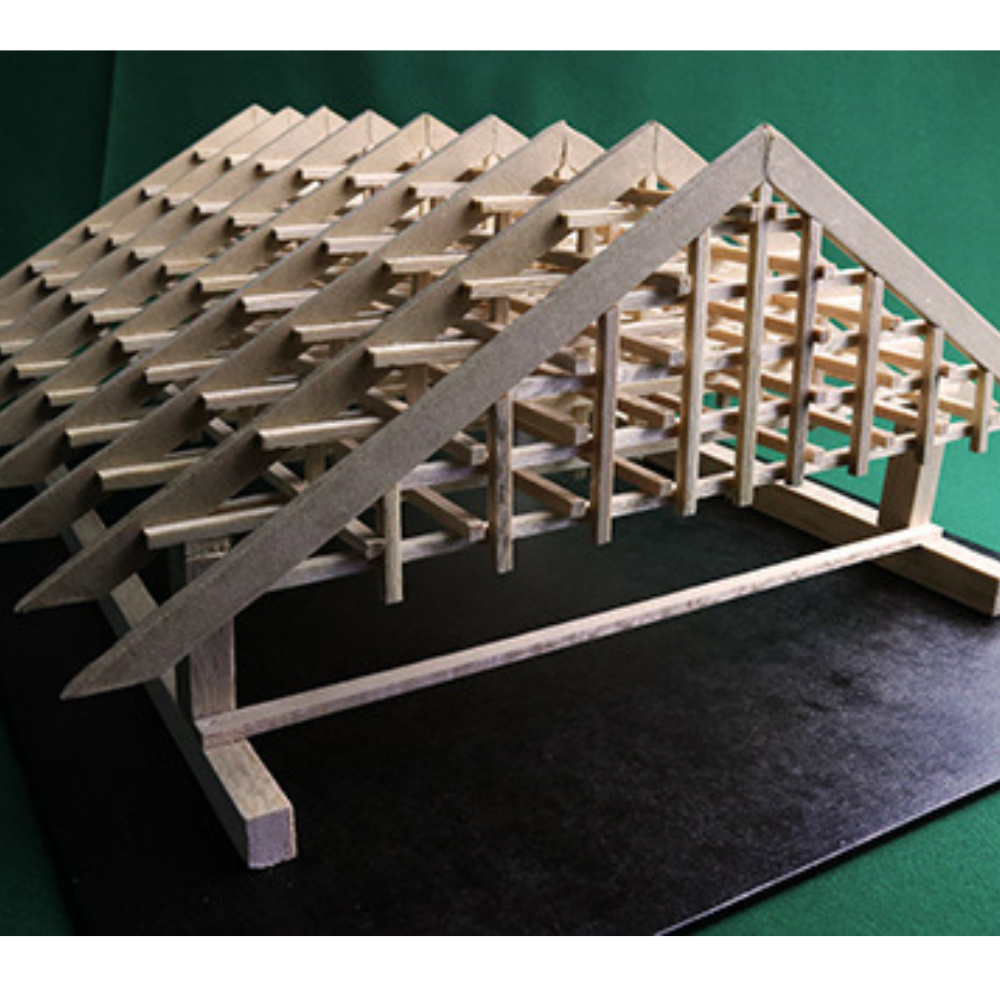

- Sticks and Strips: Often used in architectural models and bridge building competitions.

For your “Free” 2 in 1 Folding Picnic Table Bench Plan – Click Here.

Choosing the Right Balsa Wood

To choose the best balsa wood for your project, consider the following:

- Density: The wood’s density can vary, affecting its strength and weight.

- Grain Direction: Understanding grain direction is crucial for maximizing strength and aesthetics in your project.

Tools for Balsa Woodworking

The simplicity of balsa woodworking means you don’t need specialized tools. Key tools include:

- Sharp Blades: Craft knives and scalpel blades are essential for precise cuts.

- Fine Grit Sandpaper: For smooth finishes on balsa surfaces.

- Specialty Glues: Some projects may require specific types of adhesives, such as CA (cyanoacrylate) for stronger bonds.

Preparing Balsa Wood for Projects

Proper preparation of balsa wood can enhance your project’s outcome. This includes:

- Conditioning: Sometimes, lightly dampening the wood can make it more pliable for bending.

- Storage: Keep balsa wood in a cool, dry place to prevent warping.

Basic Techniques in Balsa Woodworking

Familiarize yourself with fundamental techniques to improve your skill set:

- Cutting and Shaping: Practice making clean, straight cuts and experiment with gentle curves.

- Sanding Techniques: Learn how to sand along the grain to avoid tearing the wood.

- Assembly Tips: Plan your assembly process to minimize stress on delicate parts.

Advanced Crafting with Balsa Wood

As you gain confidence, you can tackle more complex projects like detailed scale models or custom-designed decorative pieces that require intricate cuts and assembly.

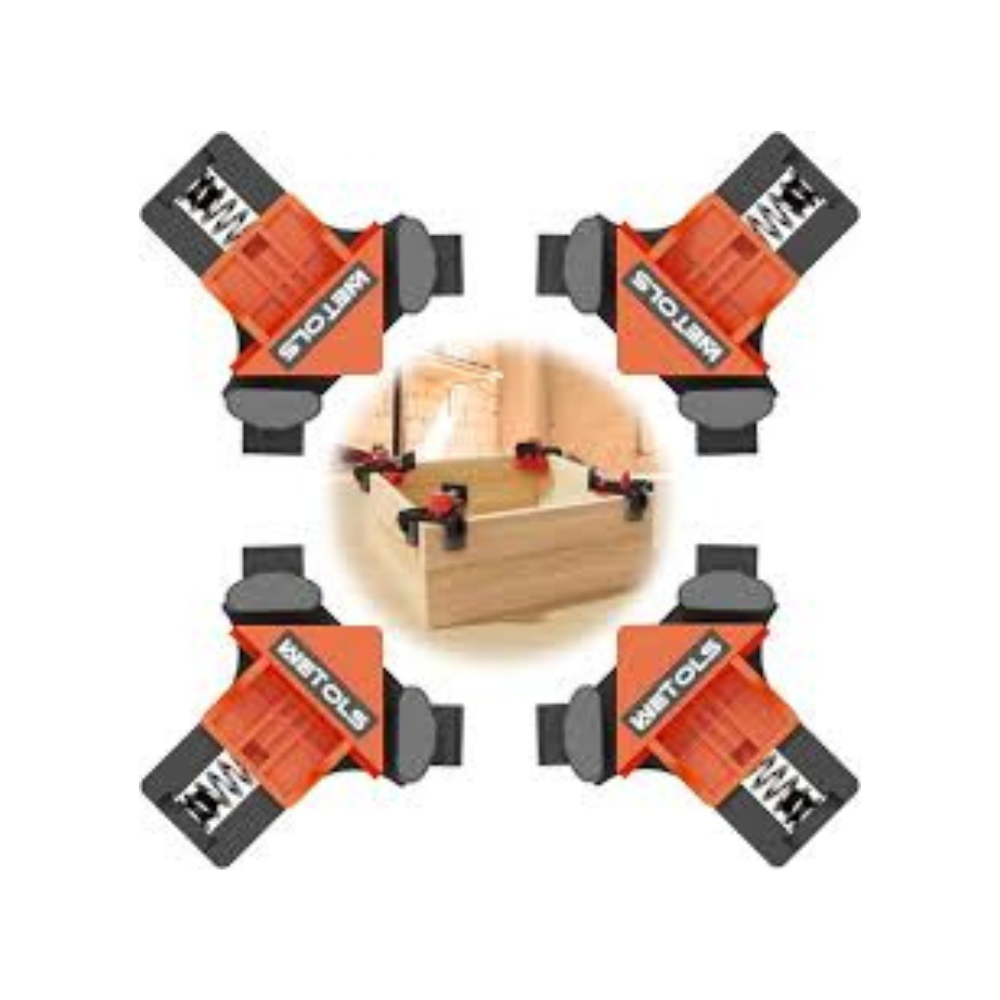

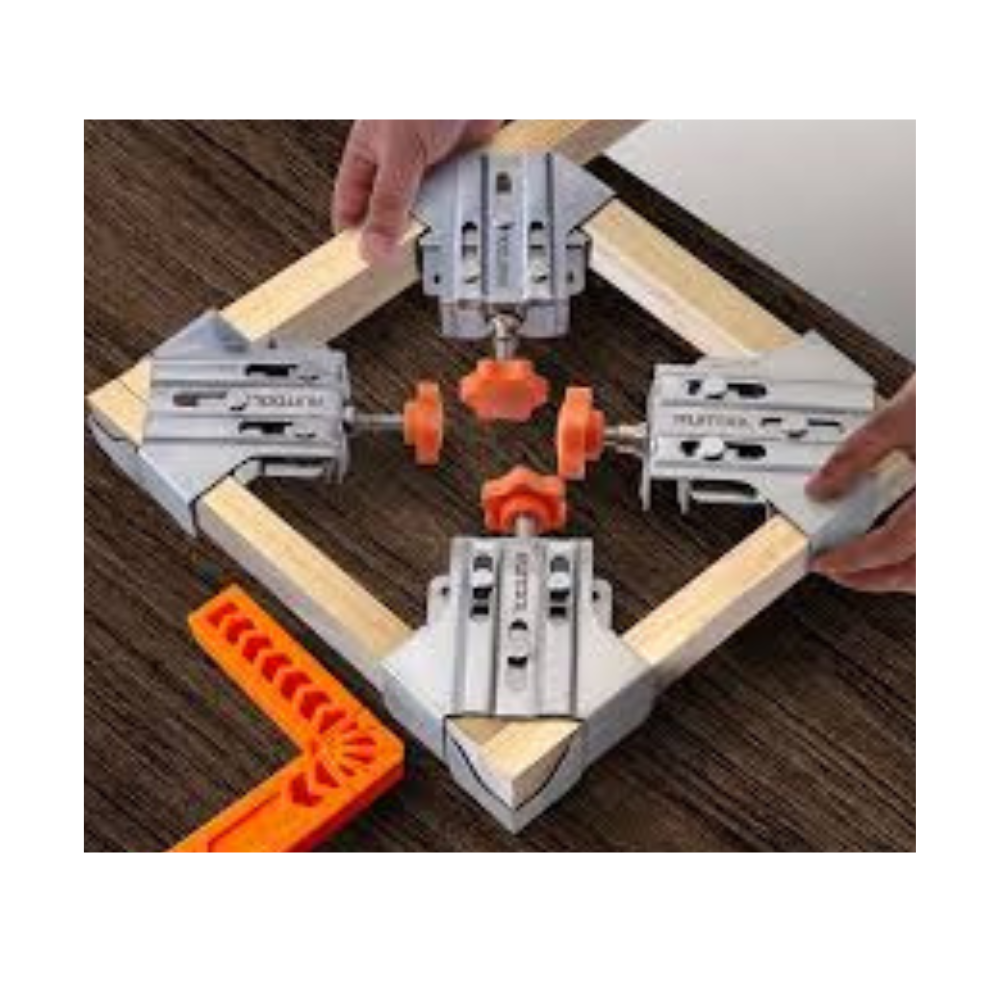

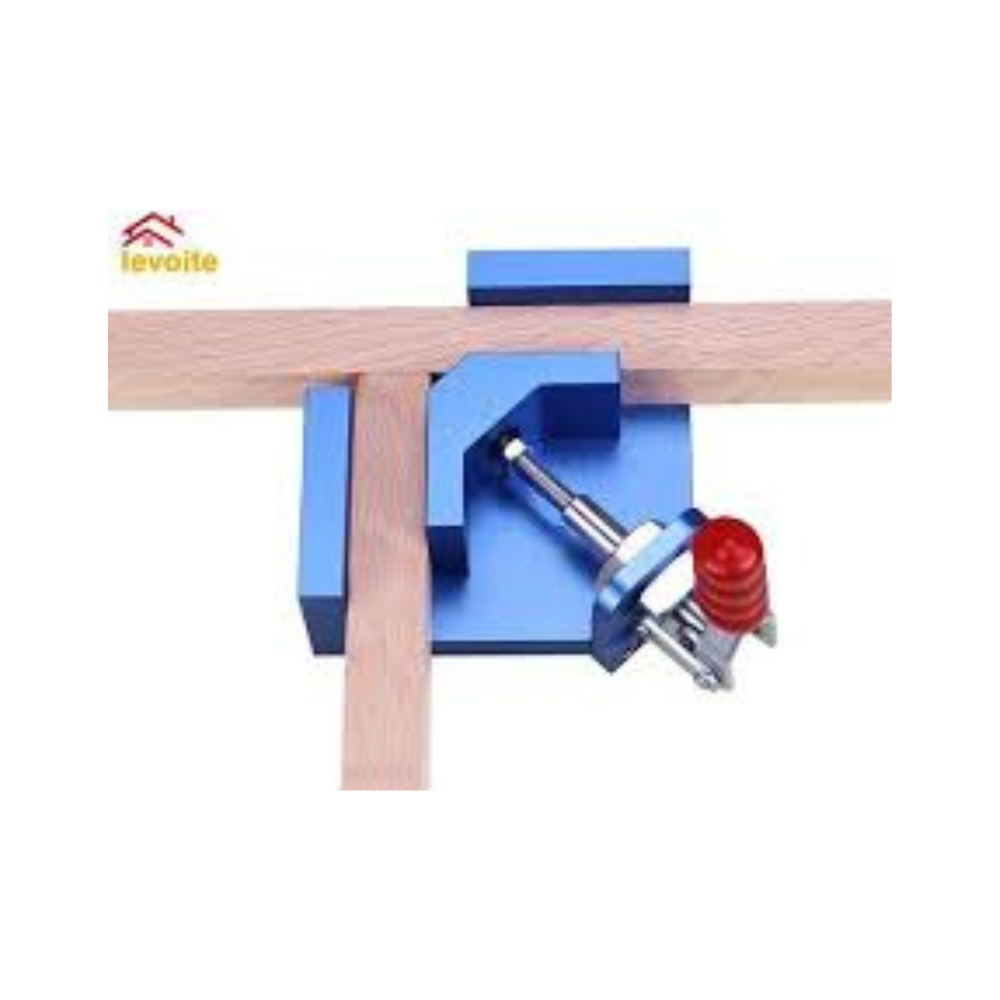

Joining Techniques for Balsa Wood

Effective joining techniques are crucial for balsa woodworking:

- Pinning with Micro Fasteners: For adding extra strength to joints.

- Epoxy Bonds: When stronger adhesion is necessary, especially in structural projects.

Decorative Techniques in Balsa Woodworking

Unleash your creativity with these decorative techniques:

- Wood Burning: Create unique patterns and designs.

- Staining and Painting: Enhance the natural beauty of balsa with various finishes.

Maintaining Balsa Wood Projects

To maintain the beauty and integrity of your balsa wood creations:

- Proper Cleaning: Use gentle, non-water-based cleaners to avoid damaging the wood.

- Regular Inspections: Check for any signs of damage or wear, especially if the item is frequently handled.

Projects Ideas for Balsa Woodworking

Here are some project ideas to get you started or inspire your next creation:

- Model Airplanes: Balsa’s light weight makes it perfect for flying models.

- Decorative Boxes: Use thin balsa sheets for delicate, lightweight boxes.

- Miniature Furniture: Craft detailed furniture for dollhouses.

Balsa Woodworking for Educational Purposes

Balsa is an excellent material for educational projects:

- STEM Learning: Build bridges or towers to teach principles of engineering and physics.

- Art Projects: Allow students to explore their artistic abilities through sculpture and model making.

Environmental Impact of Balsa Woodworking

Balsa wood is a sustainable resource, but it’s important to source it responsibly. Consider the following:

- Sourcing: Choose suppliers who harvest balsa sustainably.

- Recycling: Balsa wood pieces can often be reused in different projects.

Summary: Unleashing Creativity with Balsa Woodworking

Balsa woodworking is a rewarding hobby that combines the joys of crafting with the satisfaction of creating something both beautiful and functional. With the right tools, techniques, and a bit of creativity, you can transform simple pieces of balsa wood into impressive works of art.

For your “Free”Guide to 13 Wood Joinery Types – Click Here.

FAQs About Balsa Woodworking

- Is balsa wood easy to paint? Yes, balsa takes paint very well due to its absorbent nature, but always use a primer to achieve the best finish.

- How do you join balsa wood pieces securely? For best results, use wood-specific glues or epoxy resins designed for lightweight materials.

- Can balsa wood be sealed for outdoor use? While balsa is not typically recommended for outdoor use, sealing it with a waterproof varnish can extend its durability under covered areas.

- What safety precautions should be taken when working with balsa wood? Although balsa is relatively safe to work with, always wear a dust mask when sanding and cutting to avoid inhaling fine particles.

- Where can I learn more about balsa woodworking techniques? Many woodworking hobby shops offer classes, and there are numerous online forums and websites dedicated to model building and woodworking where you can learn more and share ideas.

Balsa woodworking not only provides a platform for developing your woodworking skills but also offers a gateway to exploring more intricate and rewarding projects. Whether you’re crafting a tiny replica or designing a custom piece of art, balsa wood is an excellent medium to work with.