Are you passionate about creating stunning and functional pieces with your own hands? If so, woodworking outdoor furniture might be the perfect project for you. This activity not only allows you to enjoy the satisfaction of building something beautiful and practical but also provides a wonderful way to enhance your outdoor living space. In this article, we’ll explore the ins and outs of woodworking outdoor furniture, from selecting the right materials to mastering essential techniques.

For your “Free” Outdoor Projects Plan – Click Here.

Introduction to Woodworking Outdoor Furniture

Woodworking outdoor furniture is a rewarding hobby that combines creativity, craftsmanship, and practicality. Whether you’re a seasoned woodworker or a beginner, building outdoor furniture can be a fun and fulfilling project. The best part? You get to enjoy the fruits of your labor every time you relax in your backyard.

Why Choose Woodworking Outdoor Furniture?

Why should you consider woodworking outdoor furniture for your next project? Here are a few reasons:

- Customization: You can tailor your furniture to fit your specific needs and tastes.

- Quality: When you build your own furniture, you have control over the materials and construction methods, ensuring higher quality.

- Satisfaction: There’s a unique sense of accomplishment that comes from creating something with your own hands.

- Cost-Effective: Building your own furniture can often be more affordable than purchasing high-quality pieces.

Selecting the Right Wood for Outdoor Furniture

Choosing the right wood is crucial for the longevity and durability of your outdoor furniture. Here are some popular choices:

- Teak: Known for its natural resistance to weather and insects, teak is a top choice for outdoor furniture.

- Cedar: Cedar is lightweight, easy to work with, and naturally resistant to decay.

- Redwood: Like cedar, redwood is resistant to moisture and insects, making it ideal for outdoor use.

- Acacia: Acacia wood is durable and offers a beautiful finish, though it may require regular maintenance.

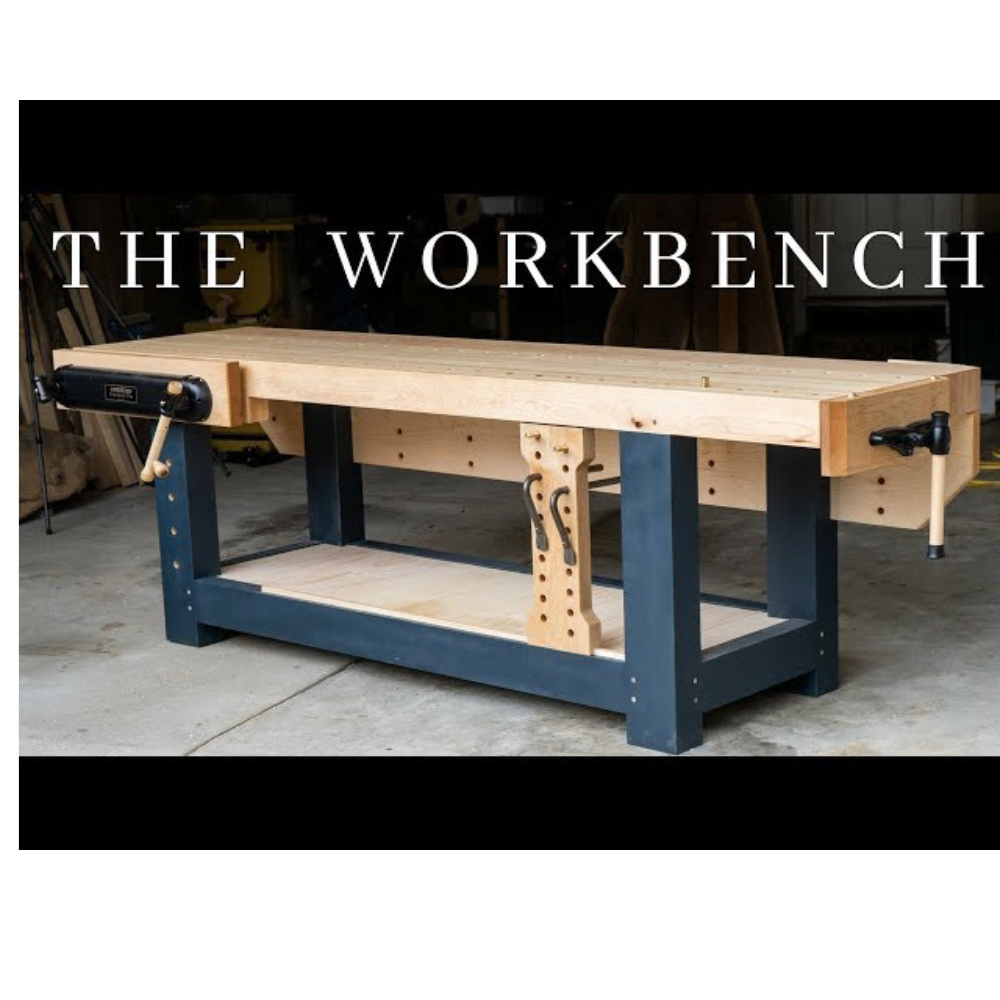

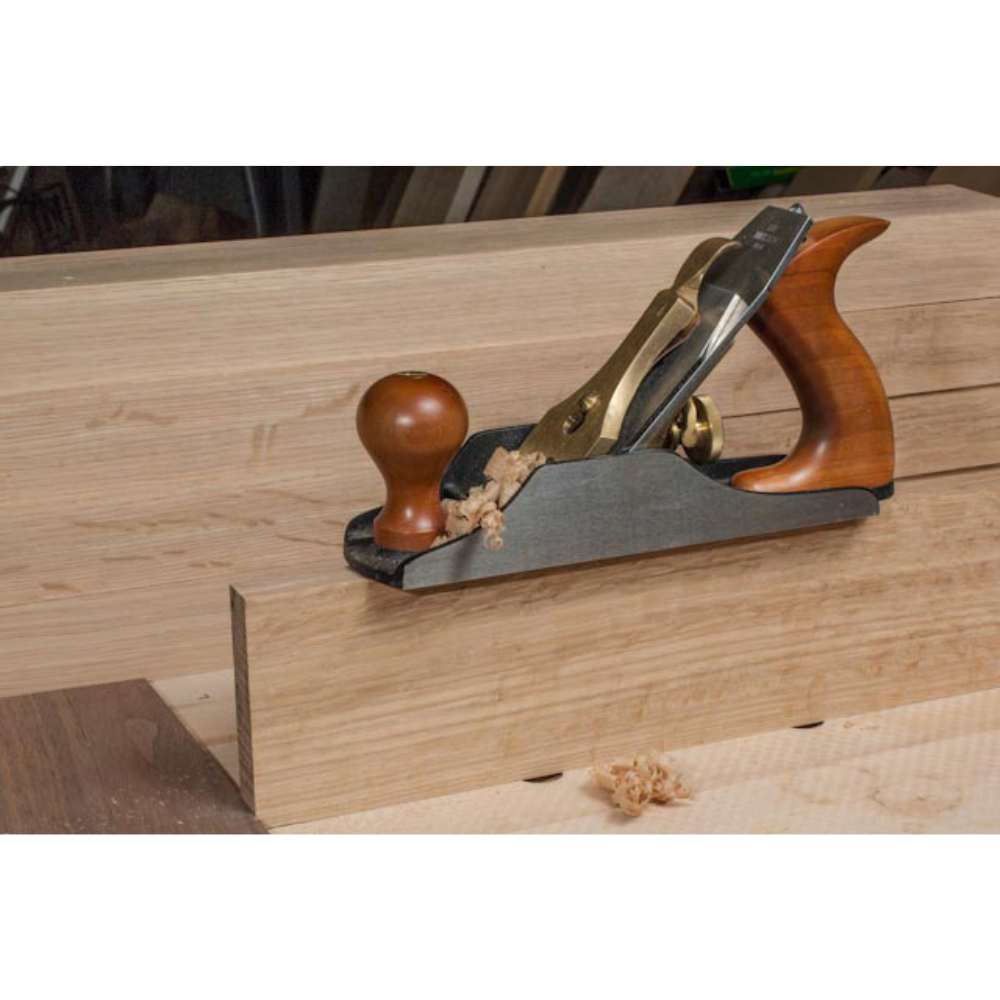

Essential Tools for Woodworking Outdoor Furniture

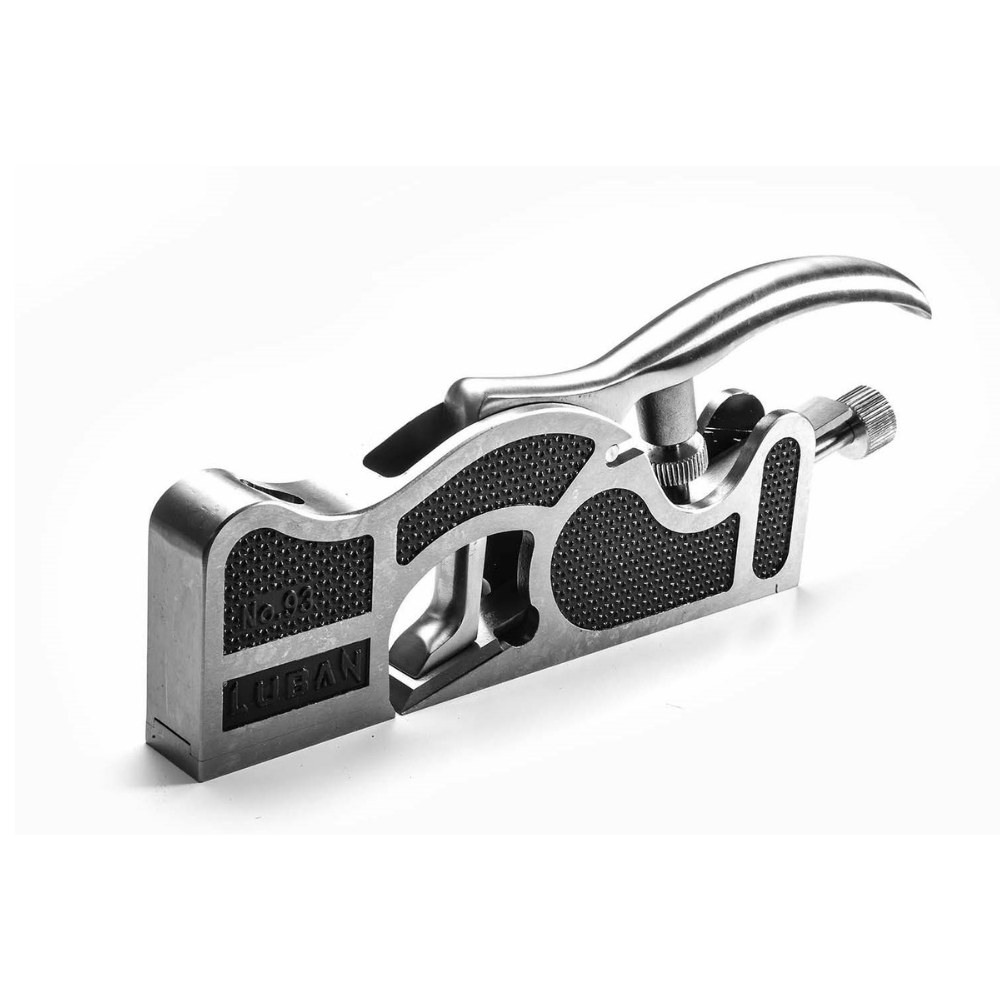

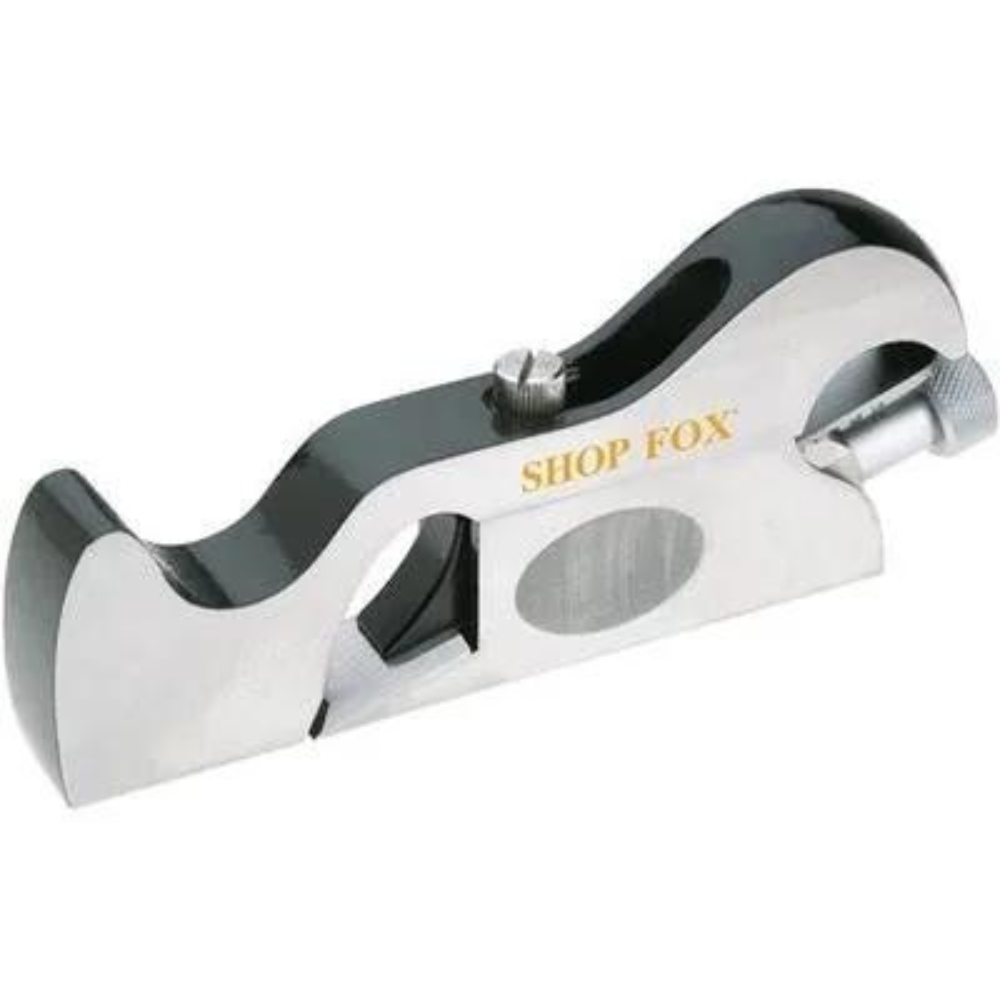

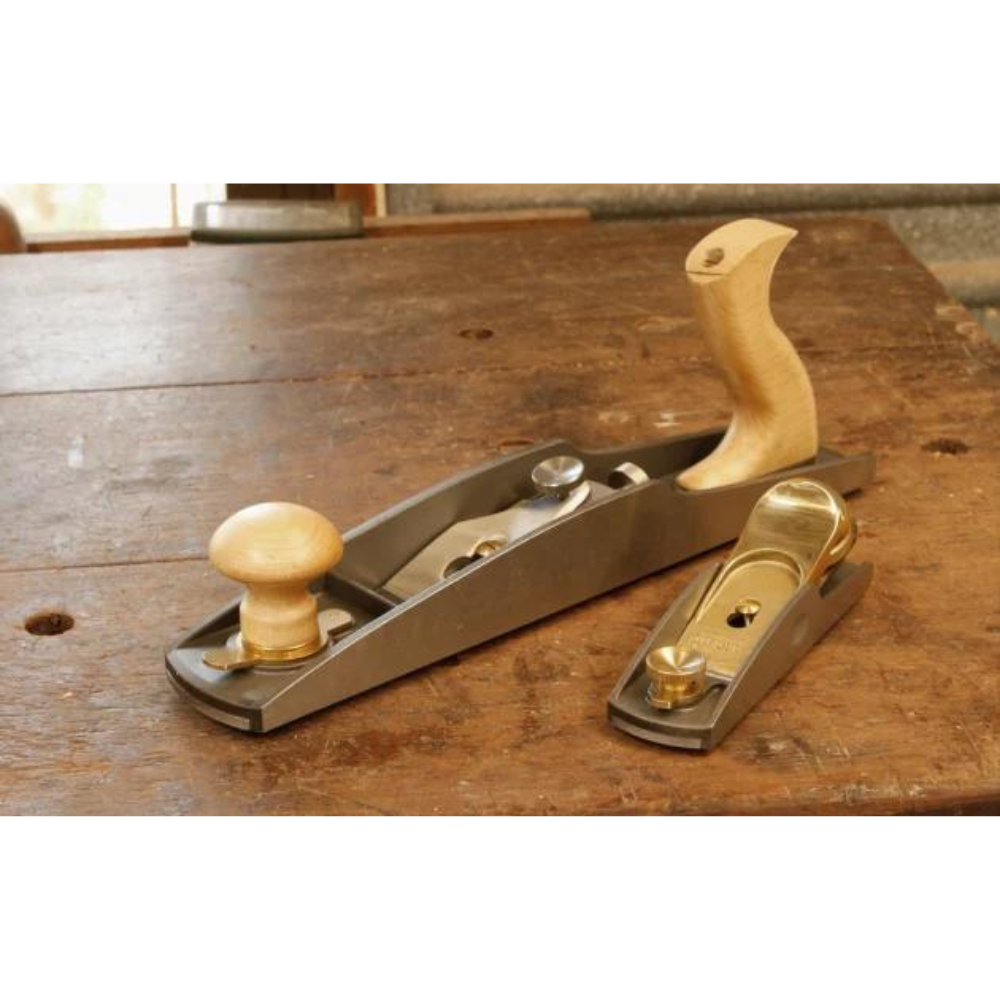

Before you start building, make sure you have the right tools. Here are some must-haves:

- Measuring Tape: Accurate measurements are crucial for a successful project.

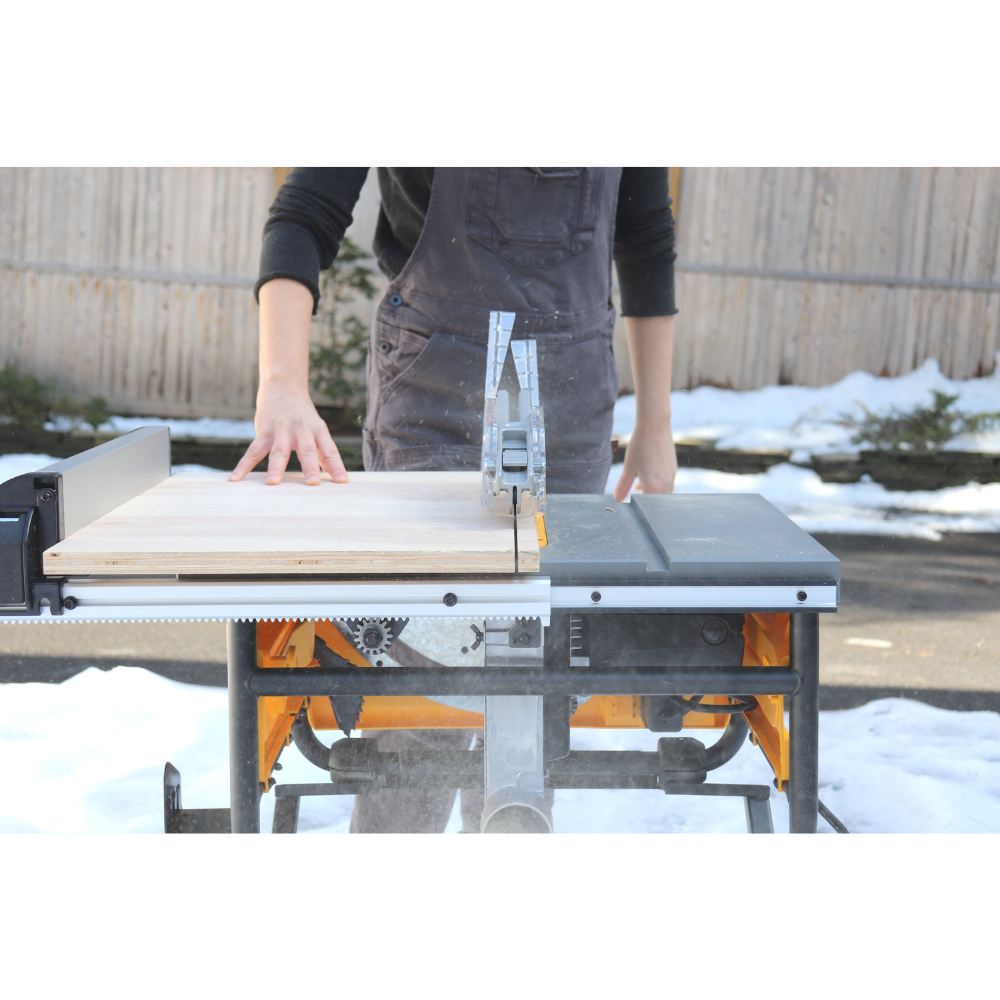

- Saw: A good saw, whether it’s a hand saw, circular saw, or miter saw, is essential for cutting wood to size.

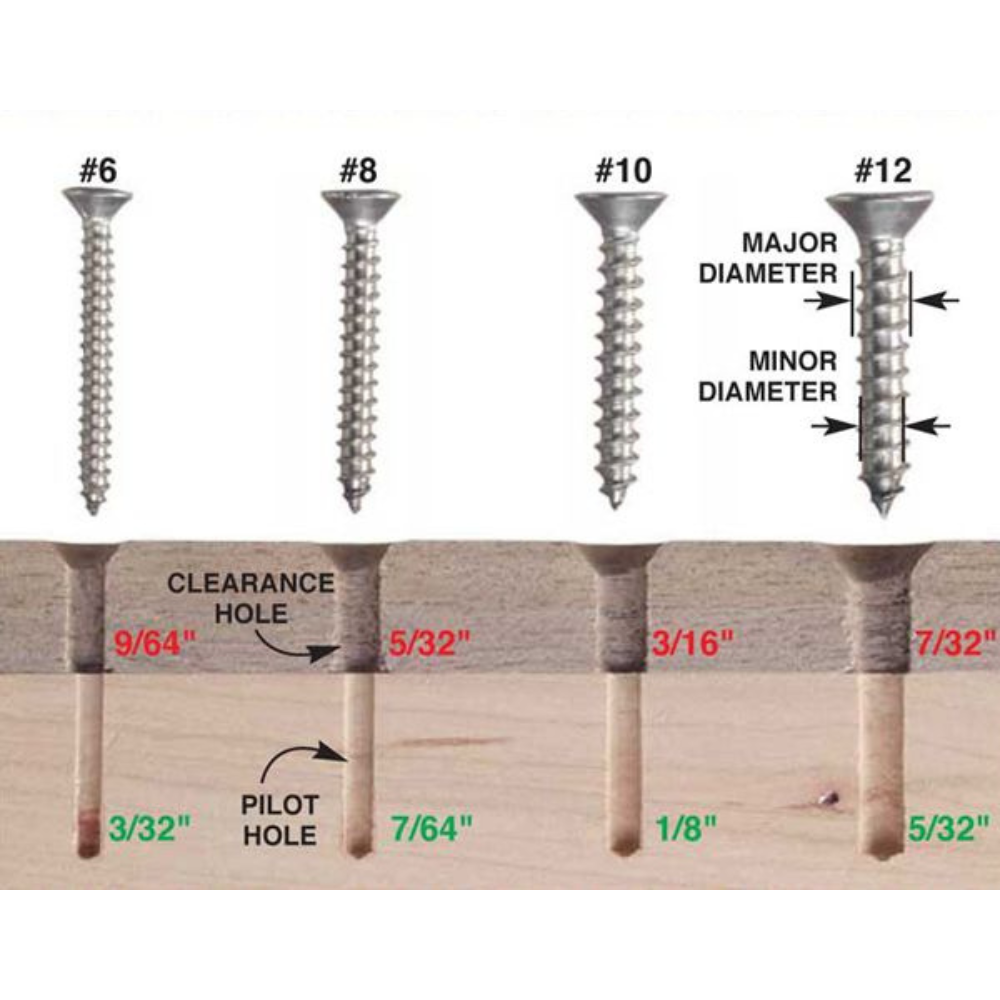

- Drill: A drill is necessary for creating holes and driving screws.

- Sander: A sander helps you achieve a smooth finish on your pieces.

- Clamps: Clamps hold your pieces together securely while the glue dries.

Safety Tips for Woodworking

Safety should always be a priority when working with tools and wood. Here are some tips:

- Wear Safety Gear: Always wear safety glasses, ear protection, and a dust mask.

- Keep Your Work Area Clean: A cluttered workspace can lead to accidents.

- Use Tools Properly: Read the manuals and understand how to use each tool safely.

- Take Your Time: Rushing can lead to mistakes and injuries.

Designing Your Outdoor Furniture

Designing your own furniture allows you to create pieces that fit your style and needs perfectly. Here are some design tips:

- Consider the Space: Measure your outdoor area to ensure your furniture fits well.

- Think About Functionality: Decide how you want to use the space and design your furniture accordingly.

- Incorporate Comfort: Add cushions, armrests, and other features to make your furniture comfortable.

- Choose a Style: Whether you prefer modern, rustic, or traditional designs, choose a style that complements your outdoor space.

Building a Simple Outdoor Chair

Let’s start with a simple project: an outdoor chair. Here’s a step-by-step guide:

- Gather Materials: You’ll need wood (cedar or redwood is ideal), screws, wood glue, and outdoor finish.

- Cut the Pieces: Measure and cut the wood pieces for the seat, backrest, and legs.

- Assemble the Frame: Use screws and wood glue to assemble the chair frame.

- Attach the Seat and Backrest: Secure the seat and backrest to the frame.

- Sand and Finish: Sand the entire chair and apply an outdoor finish to protect the wood.

Creating a Sturdy Outdoor Table

An outdoor table is another great project. Here’s how to build one:

- Select Your Wood: Teak or acacia are excellent choices.

- Cut the Tabletop Pieces: Measure and cut the pieces for the tabletop.

- Build the Frame: Assemble the table frame using screws and wood glue.

- Attach the Tabletop: Secure the tabletop to the frame.

- Finish the Table: Sand the table and apply a weather-resistant finish.

Building a Beautiful Garden Bench

A garden bench can be a beautiful addition to your outdoor space. Follow these steps:

- Choose Your Wood: Cedar or redwood works well for benches.

- Cut the Bench Pieces: Measure and cut the pieces for the seat, backrest, and legs.

- Assemble the Frame: Use screws and wood glue to build the bench frame.

- Attach the Seat and Backrest: Secure the seat and backrest to the frame.

- Sand and Finish: Sand the bench and apply an outdoor finish.

For your “Free” Outdoor Projects Plan – Click Here.

Maintaining Your Outdoor Furniture

Proper maintenance can extend the life of your woodworking outdoor furniture. Here are some tips:

- Clean Regularly: Wipe down your furniture with a damp cloth to remove dirt and debris.

- Reapply Finish: Depending on the wood and finish, you may need to reapply a protective finish every few years.

- Store During Winter: If possible, store your furniture indoors during the winter to protect it from harsh weather.

Decorating Your Outdoor Space

Once you’ve built your furniture, it’s time to decorate your outdoor space. Here are some ideas:

- Add Cushions: Cushions add comfort and a pop of color to your furniture.

- Use Outdoor Rugs: Outdoor rugs can define your space and add a cozy feel.

- Incorporate Lighting: String lights, lanterns, and solar lights can create a warm ambiance.

- Include Plants: Potted plants and flowers can enhance the natural beauty of your space.

Personalizing Your Outdoor Furniture

Personalizing your furniture can make it feel uniquely yours. Consider these options:

- Paint or Stain: Add a splash of color or a rich stain to match your style.

- Carving: If you’re skilled with a chisel, add decorative carvings to your pieces.

- Engraving: Personalize your furniture with engravings of your initials, a favorite quote, or a special date.

Troubleshooting Common Issues

Encountering problems during your woodworking outdoor furniture project is normal. Here are some common issues and solutions:

- Warped Wood: Ensure your wood is properly dried before use and store it in a dry place.

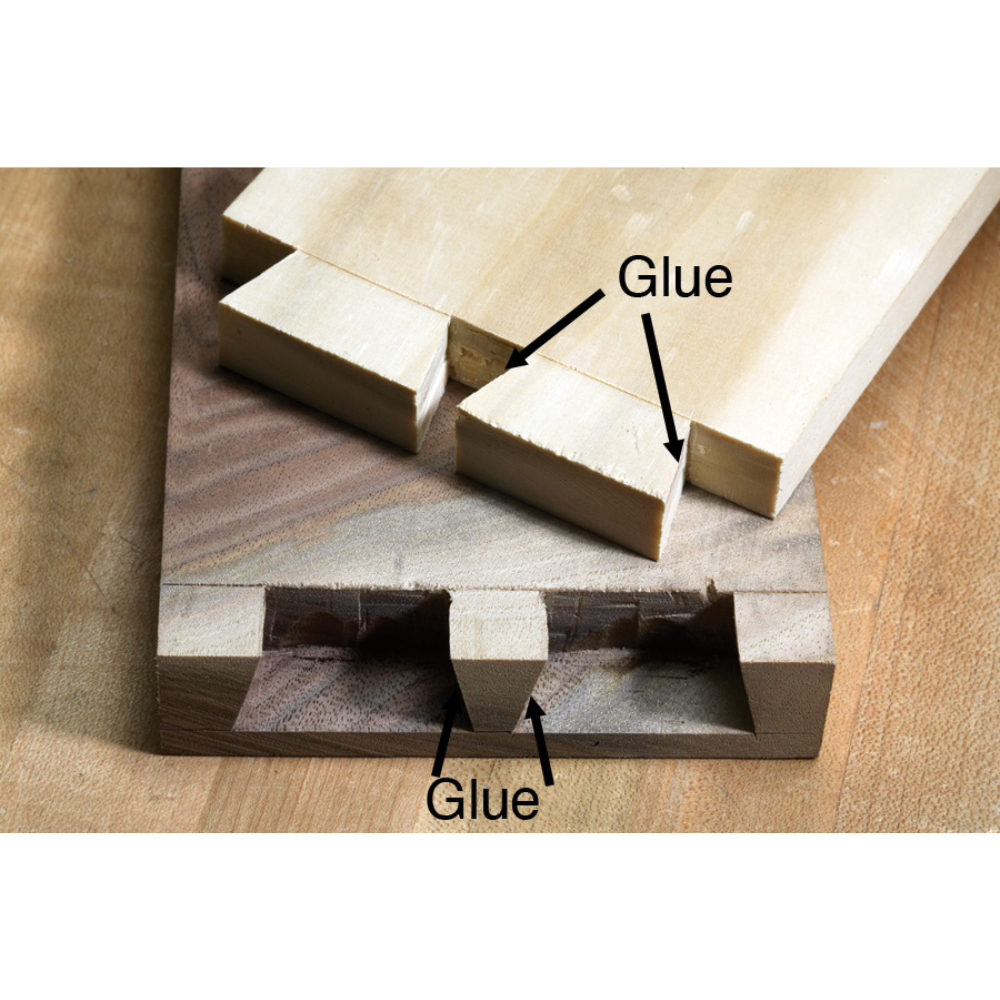

- Loose Joints: Use quality wood glue and clamps to secure joints tightly.

- Rough Edges: Sand thoroughly and use finer sandpaper for a smooth finish.

Advanced Techniques for Experienced Woodworkers

If you’re an experienced woodworker, consider trying these advanced techniques:

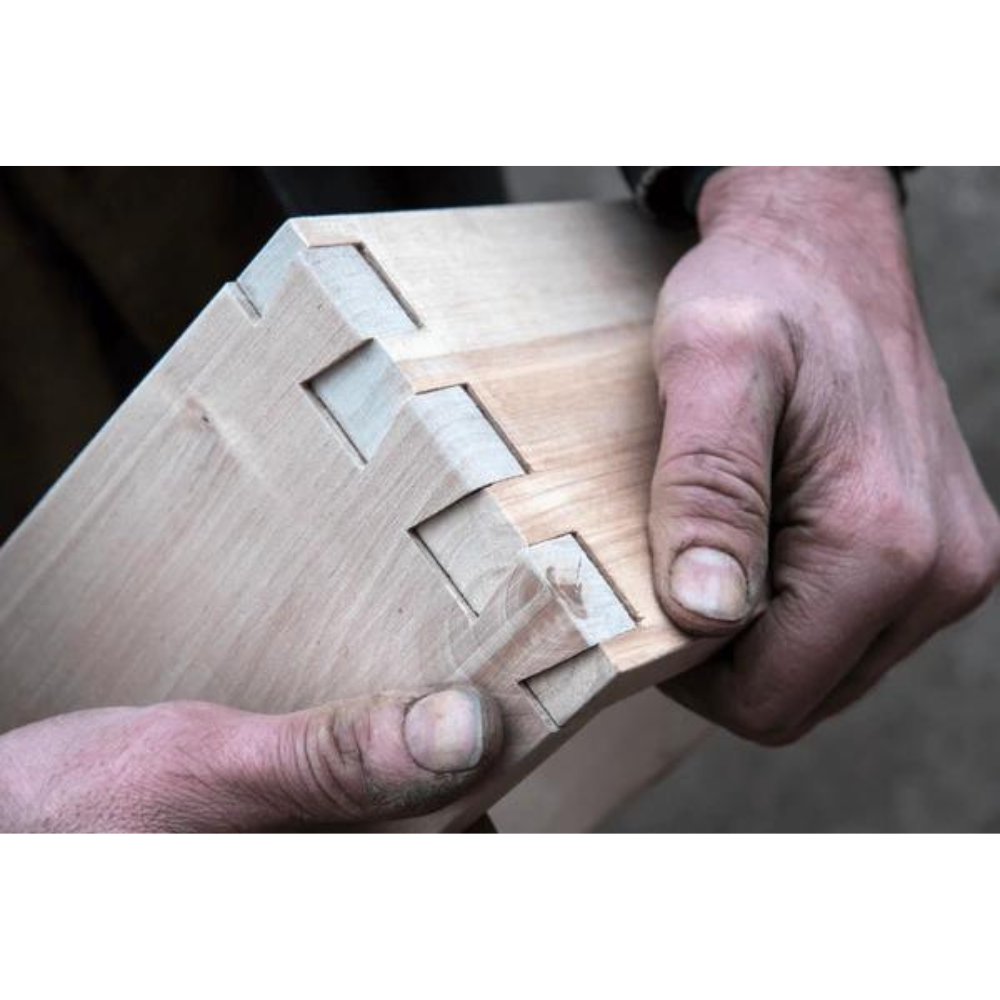

- Joinery: Techniques like dovetail, mortise and tenon, and finger joints can add strength and beauty to your furniture.

- Bending Wood: Steam bending or laminating thin strips can create curved designs.

- Inlay: Add decorative inlays using contrasting wood or materials like metal or stone.

The Benefits of DIY Outdoor Furniture

Building your own outdoor furniture has many benefits:

- Creativity: You can design pieces that are uniquely yours.

- Skill Development: Each project helps you improve your woodworking skills.

- Sustainability: Using sustainable wood and eco-friendly finishes can make your project environmentally friendly.

- Community: Sharing your creations with friends and family can inspire others to start woodworking.

For your “Free” Outdoor Projects Plan – Click Here.

Conclusion

Woodworking outdoor furniture is a fulfilling and practical hobby that allows you to create beautiful, functional pieces for your outdoor space. From choosing the right wood and tools to mastering essential techniques and advanced methods, there’s always something new to learn and create. Whether you’re building a simple chair, a sturdy table, or a beautiful garden bench, the possibilities are endless.

FAQs about Woodworking Outdoor Furniture

1. What is the best wood for outdoor furniture?

Teak, cedar, redwood, and acacia are excellent choices for outdoor furniture due to their natural resistance to weather and insects.

2. How do I protect my outdoor furniture from the elements?

Applying a weather-resistant finish, such as outdoor varnish or sealant, and storing your furniture indoors during harsh weather can protect it from the elements.

3. Can beginners build outdoor furniture?

Yes, beginners can start with simple projects like chairs or small tables. There are many resources and tutorials available to help you get started.

4. How do I maintain my outdoor furniture?

Regular cleaning, reapplying protective finishes, and storing furniture indoors during the winter are key maintenance practices.

5. What tools do I need to start woodworking outdoor furniture?

Essential tools include a measuring tape, saw, drill, sander, and clamps. Safety gear like safety glasses, ear protection, and a dust mask are also important.

By following these tips and techniques, you can create stunning woodworking outdoor furniture that will enhance your outdoor living space and provide you with a great sense of accomplishment. So, grab your tools and get started on your next woodworking adventure!