Introduction to Kinds of Joints in Carpentry

Diving into woodworking requires a solid grasp of the kinds of joints in carpentry. These joints are fundamental in constructing both functional and decorative pieces. Whether you’re crafting a simple bookshelf or an elaborate dining room table, the integrity of your work depends heavily on the joints you choose. This article will guide you through the myriad options available, their applications, and tips on selecting the right joint for any project.

For your “Free” Guide to 13 Wood Joinery Types – Click Here.

What is a Carpentry Joint?

A carpentry joint connects two or more pieces of wood. The method of connection ranges from basic mechanical fastenings, like screws and nails, to more complex interlocking designs. Factors such as the project’s aesthetic goals, structural requirements, and the woodworker’s skill level influence the choice of joint.

Why the Right Kinds of Joints in Carpentry Matter

The functionality and longevity of a wooden structure greatly depend on the appropriate selection of joint type. A well-chosen joint ensures durability and enhances the piece’s beauty. Conversely, a poor joint choice can lead to structural failures or aesthetic discrepancies that compromise the project’s quality.

Basic Kinds of Joints in Carpentry Explained

1. Butt Joint: Simplicity in Action

The butt joint is the most basic type, where the ends of two pieces of wood are butted together and fixed, usually with nails, screws, or glue. While simple and quick to make, butt joints are relatively weak and often require reinforcement with other joint types for added stability.

2. Miter Joint: Elegance in Angles

Miter joints involve cutting two pieces of wood at an angle, most often 45 degrees, so they form a perfect right angle when joined. This type of joint is commonly used for frames and decorative trims, where a seamless appearance is crucial.

3. Lap Joint: Overlapping Strength

A lap joint forms by overlapping two pieces of wood, either fully or partially. It provides more strength than a butt joint due to the increased surface area for adhesion and is particularly effective in frame construction.

Advanced Types of Carpentry Joints

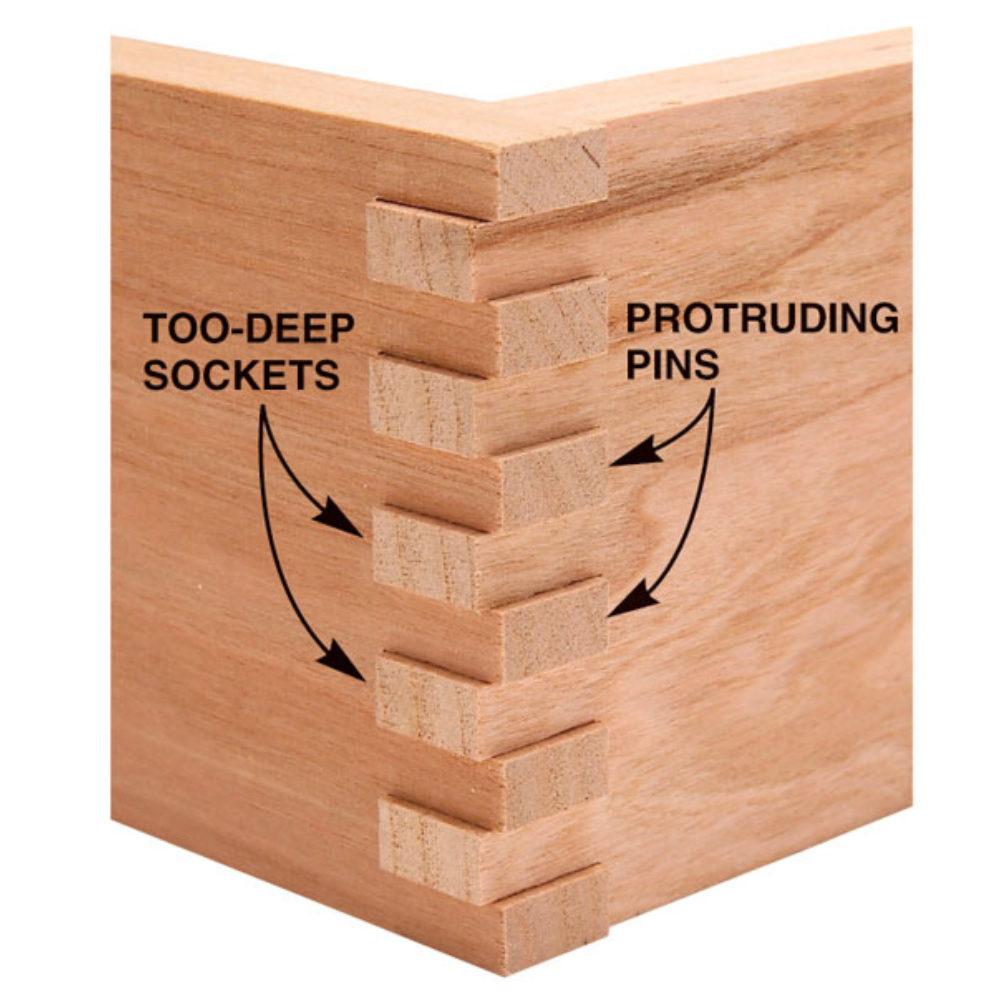

4. Dovetail Joint: Interlocking Mastery

The dovetail joint, with its interlocking fingers, resists being pulled apart and offers visual appeal, making it ideal for drawer construction and fine cabinetmaking. This joint is complex to make but provides excellent durability and strength.

5. Mortise and Tenon Joint: Time-Tested Durability

One of the oldest and strongest joints in woodworking, the mortise and tenon consists of a tenon fitting snugly into a mortise. It sees widespread use in heavy furniture and structural frames due to its impressive load-bearing capacity.

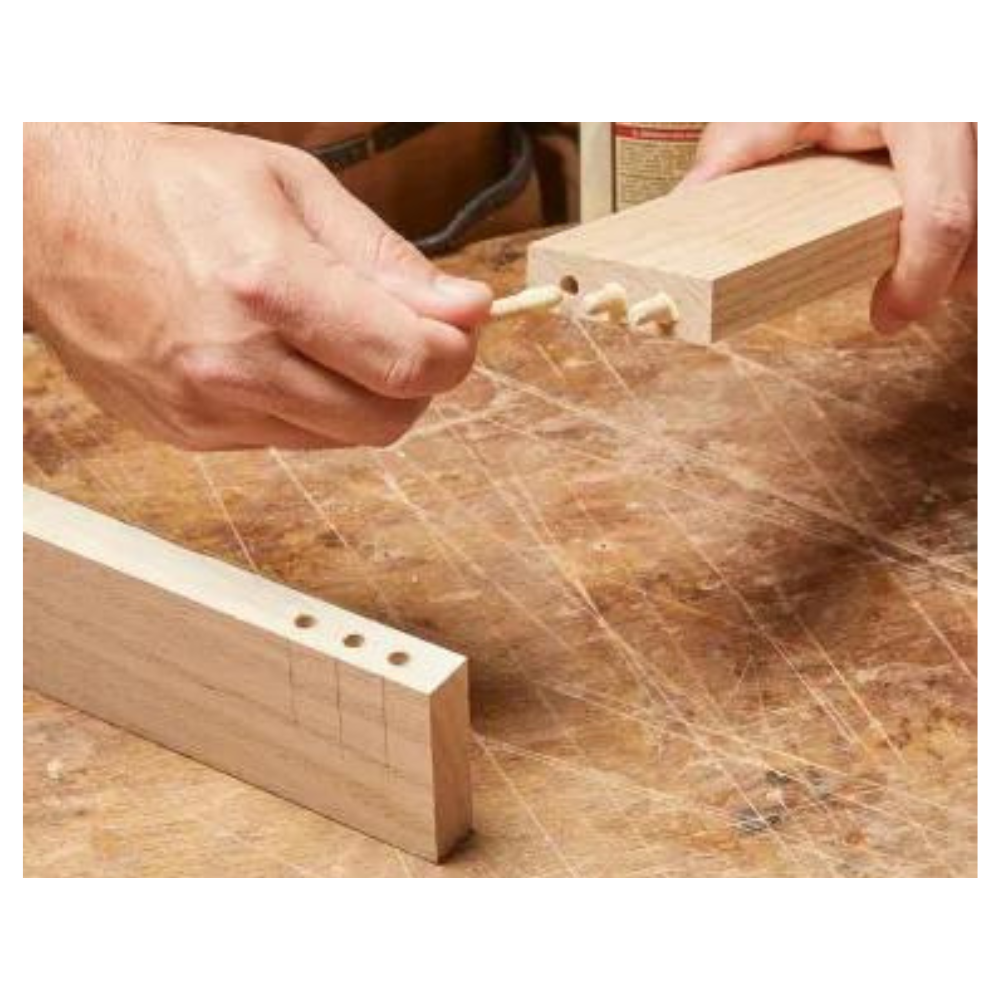

6. Dowel Joint: Precision and Strength

This joint uses small wooden pins known as dowels to connect pieces of wood. Dowel joints are strong and can be nearly invisible, which is ideal for aesthetic projects where visible nails or screws are undesirable.

Decorative and Specialty Wood Joints

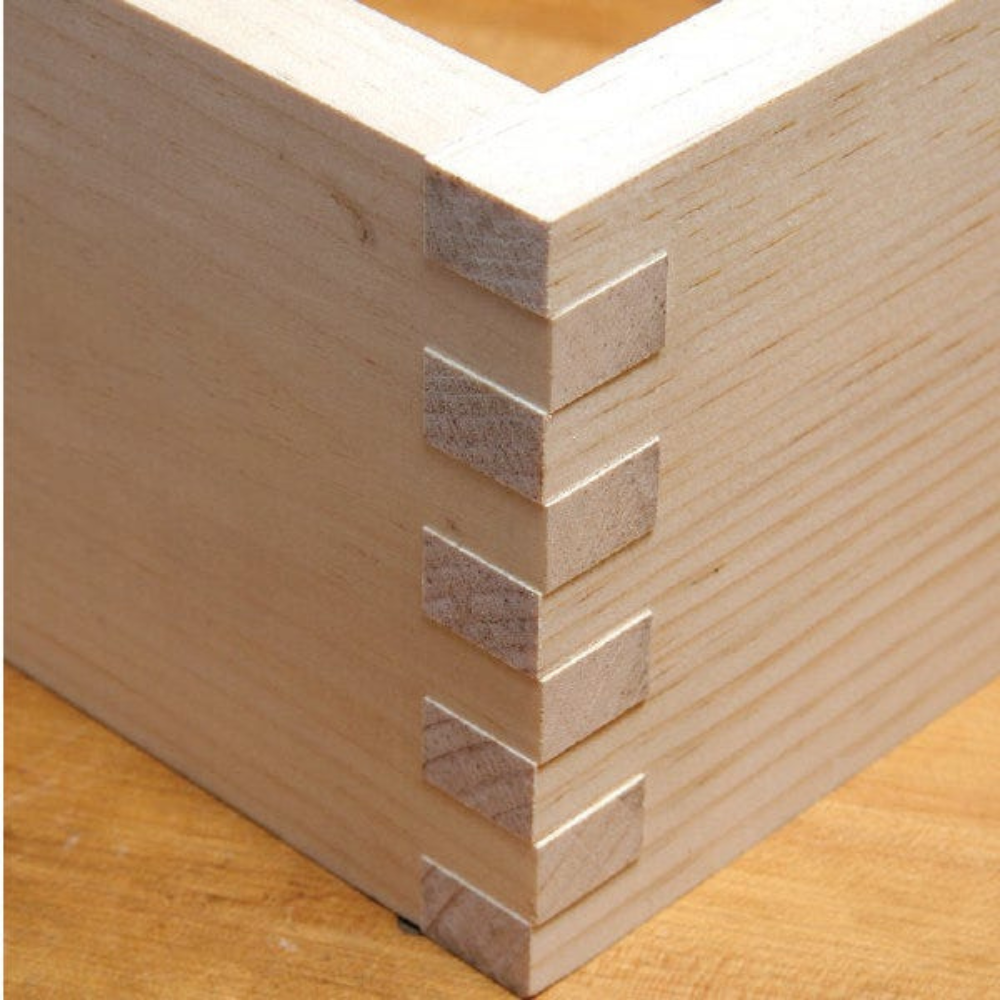

7. Finger Joint: Complex and Strong

The finger joint uses a series of interlocking fingers that are glued together. It is extremely strong and often appears in box construction and carpentry where strength is needed without the bulk of other joints.

8. Bridle Joint: Structural Elegance

A variation of the mortise and tenon, the bridle joint features a tenon on one piece and a mortise on the other, forming a T- or L-shape. It typically serves frames and general carpentry for its robustness.

For your “Free” Workspace Plans – Click Here.

9. Rabbet Joint: Built for Cabinets

A rabbet joint involves a notch or step cut into the edge of a piece of wood to receive another piece. This type of joint often appears in cabinet and bookcase backings.

10. Pocket Hole Joint: Quick and Versatile

The pocket hole joint involves drilling a hole at an angle into one piece of wood and joining it to another with a screw. It’s fast to execute and provides a strong joint with minimal visibility of hardware.

11. Biscuit Joint: Alignment and Simplicity

This joint uses small, football-shaped slices of compressed wood, known as biscuits, which are inserted into matching slots in both pieces of wood. Biscuit joints excel at aligning edges during glue-ups, making them ideal for paneling and tabletops.

Choosing the Right Kinds of Joints in Carpentry for Your Project

Selecting the appropriate joint involves considering the project’s design, the types and directions of stress it will endure, and the desired aesthetics. Matching the joint’s characteristics with the project’s requirements ensures durability and visual appeal.

Maintaining Joints in Carpentry

Maintaining the integrity of carpentry joints over time is crucial for the longevity of the piece. Regular inspections for signs of stress, wear, or failure, particularly in load-bearing areas, can prevent structural damage and extend the item’s life.

Innovations in Types of Carpentry Joints

Advancements in woodworking tools and techniques continue to produce new types of joints and improve the ease and efficiency of traditional methods. These innovations often focus on increasing strength, reducing visibility, or speeding up the construction of joints.

Conclusion: Mastering Kinds of Joints in Carpentry

Mastering the different kinds of joints in carpentry is essential for any woodworker seeking to enhance the quality and durability of their projects. From simple butt joints to intricate dovetails, each joint has specific advantages and applications. Understanding when and how to use each joint ensures your projects are not only functional but also aesthetically pleasing.

FAQs About Kinds of Woodworking Joints in Carpentry

What is the strongest joint in carpentry?

The mortise and tenon joint is often considered the strongest due to its extensive surface area and interlocking design.

Which joint is best for making a wooden box?

The finger joint offers both strength and a decorative edge, making it ideal for boxes that require durability and aesthetic appeal.

How do I choose the right joint for outdoor furniture?

Choose joints that are robust and can withstand weather elements, such as the dovetail or mortise and tenon, which provide excellent strength and durability.

Can I use multiple types of joints in a single project?

Absolutely! Combining different joints can optimize both the strength and the appearance of your project.

What tools do I need to create these joints?

Depending on the joint, you might need a variety of tools such as saws, chisels, routers, or doweling jigs. Advanced joints like dovetails may require specialized tools for precise cutting and fitting.

By familiarizing yourself with the various kinds of joints in carpentry, you can select the best joint for any scenario, ensuring your projects are robust, beautiful, and stand the test of time.