Introduction

Dovetail woodworking is one of the most admired and respected techniques in the woodworking world. Known for its strength, durability, and beautiful aesthetic, dovetail joinery is a staple in fine furniture making and cabinetry. But what exactly makes dovetail woodworking so special? How can you master this craft to create stunning, lasting pieces? In this comprehensive guide, we’ll delve into the intricacies of dovetail woodworking, providing you with the knowledge and skills to elevate your woodworking projects.

Understanding Dovetail Woodworking

1. What is Dovetail Woodworking?

Dovetail woodworking involves creating interlocking joints between two pieces of wood, often used in drawers, boxes, and furniture corners. These joints are renowned for their resistance to being pulled apart, thanks to the trapezoidal shape of the “tails” and “pins” that fit together perfectly.

2. History of Dovetail Woodworking

The art of dovetail joinery dates back thousands of years, with early examples found in ancient Egyptian furniture. Over time, dovetail woodworking has evolved, but the basic principles have remained the same, making it a timeless technique valued by craftsmen across generations.

3. Types of Dovetail Woodworking Joints

There are several types of dovetail joints, each with its unique application and aesthetic:

- Through Dovetails: Visible from both sides of the joint, often used in boxes and carcass construction.

- Half-Blind Dovetails: Visible from one side only, commonly used in drawer fronts.

- Secret Mitered Dovetails: Concealed within the miter joint, providing a clean look.

- Sliding Dovetails: Used to join boards at a right angle, offering both strength and alignment.

4. Benefits of Dovetail Woodworking Joinery

Why should you consider dovetail woodworking for your projects? Here are some compelling reasons:

- Strength and Durability: Dovetail joints are incredibly strong and can withstand significant stress.

- Aesthetic Appeal: The intricate pattern of dovetails adds a touch of craftsmanship and elegance.

- Long-Lasting: Properly made dovetail joints can last for generations.

Tools and Materials for Dovetail Woodworking

5. Essential Tools

To begin your journey into dovetail woodworking, you’ll need a few key tools:

- Dovetail Saw: A fine-toothed saw designed for making precise cuts.

- Chisels: Sharp chisels are crucial for cleaning up the joints.

- Marking Gauge: For accurate measurement and marking of your cuts.

- Mallet: Used in conjunction with chisels for controlled carving.

- Layout Tools: Such as a square and a ruler for precise measurements.

6. Choosing the Right Wood for Dovetail Woodworking

Selecting the appropriate wood is vital for successful dovetail woodworking. Hardwoods like oak, maple, and cherry are popular choices due to their durability and fine grain, which provides a smooth finish.

7. Preparing Your Workspace

A well-organized workspace is essential, ensure you have a sturdy workbench, good lighting, and ample space to maneuver your tools and materials.

Step-by-Step Guide to Making Dovetail Joints

8. Planning Your Project

Before you start cutting, plan your project thoroughly. Determine the size and type of dovetail joint you’ll be using, and sketch your design to visualize the final product.

9. Marking and Measuring dovetail woodworking

Accuracy is critical. Use your marking gauge to measure and mark the tails and pins on your wood pieces. Double-check your measurements to avoid mistakes.

10. Cutting the Tails

Using your dovetail saw, carefully cut along the marked lines for the tails. Maintain a steady hand and follow the lines precisely to ensure a snug fit.

11. Cutting the Pins

Align the tails on the second piece of wood and trace their outline. Cut along these lines to create the pins. Precision is key to achieving a perfect fit.

12. Cleaning Up the Joints on dovetail woodworking

Use chisels to clean up the cuts, ensuring the tails and pins fit together seamlessly. Patience and attention to detail are crucial at this stage.

For your “Free” Workspace Plans – Click Here.

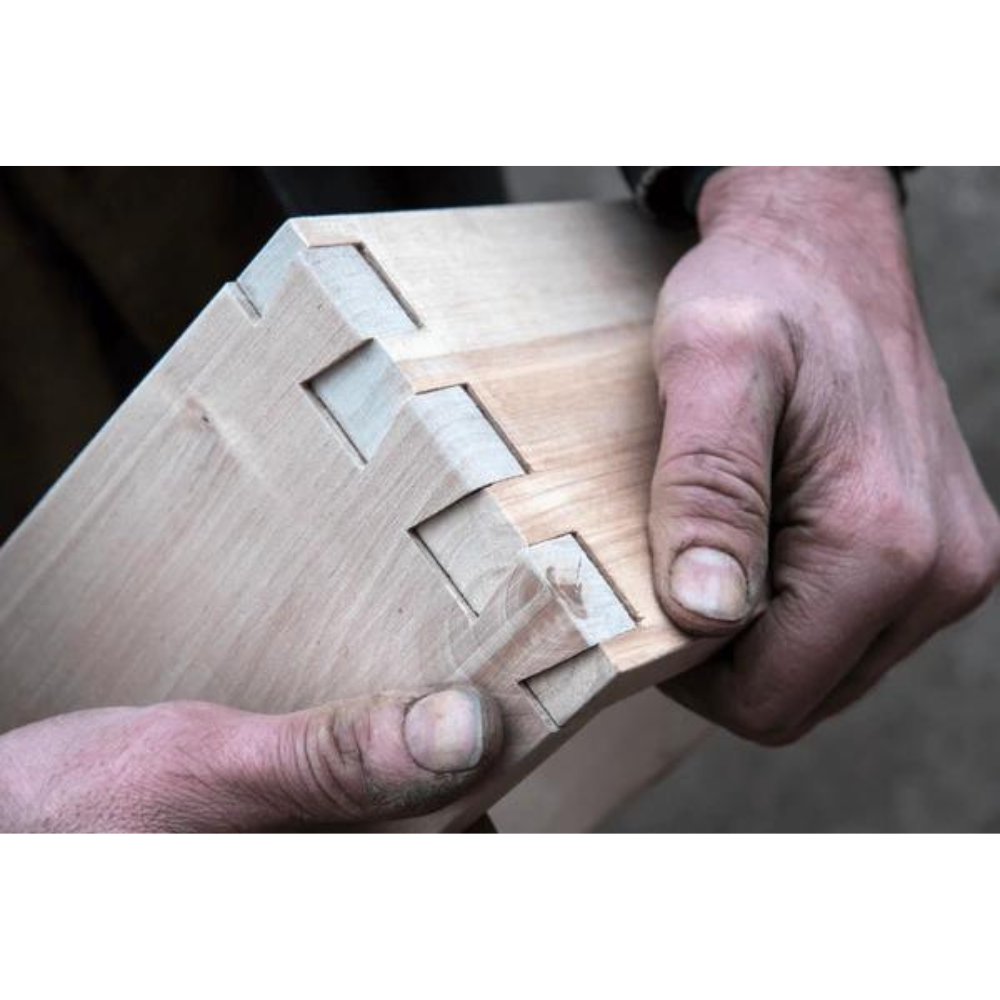

13. Dry Fitting the Joints

Before applying glue, dry fit the joints to check for any adjustments needed. The pieces should fit together snugly without gaps.

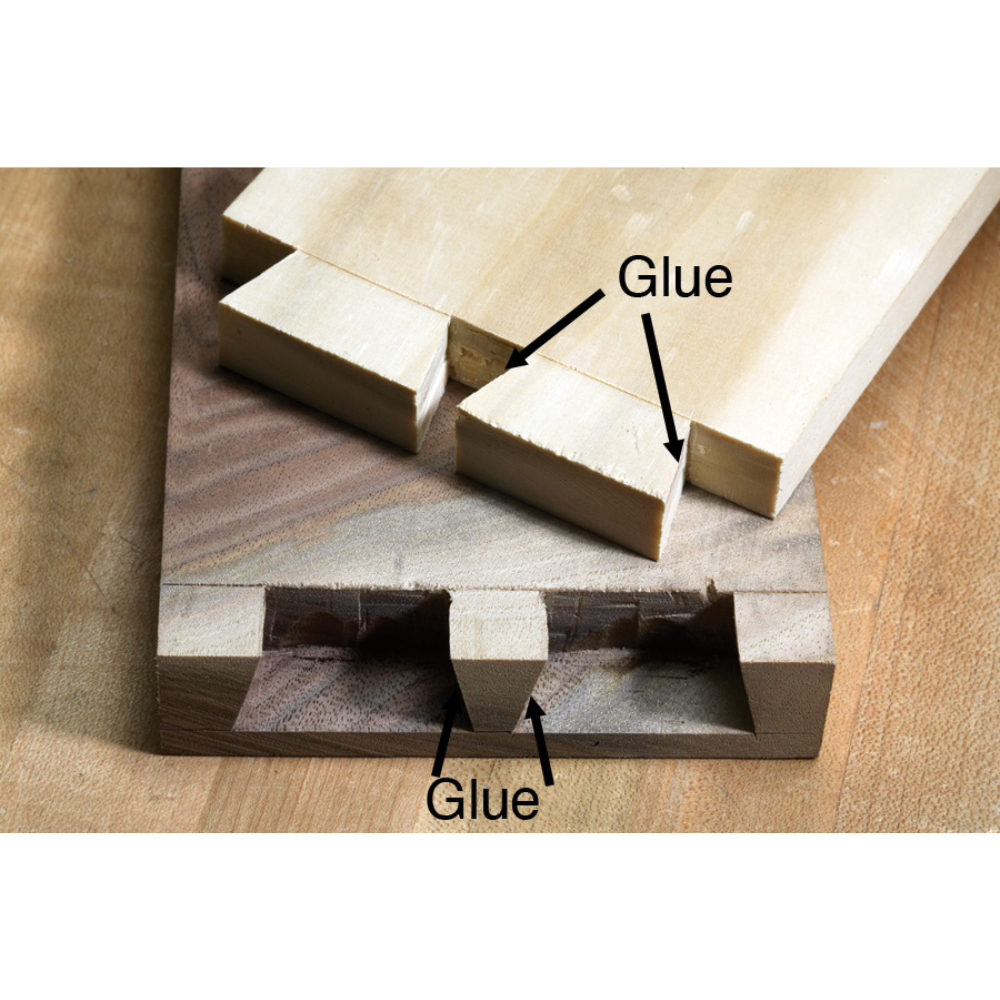

14. Gluing and Clamping dovetail woodworking

Apply wood glue to the joints and clamp them together securely. Wipe off any excess glue and allow it to dry according to the manufacturer’s instructions.

Advanced Techniques in Dovetail Woodworking

15. Decorative Dovetails

Once you’ve mastered the basics, experiment with decorative dovetails. This involves varying the size and shape of the tails and pins for a unique, artistic look.

16. Incorporating Inlays

Adding inlays to your dovetail joints can enhance their visual appeal. Use contrasting wood or other materials to create striking designs.

17. Using Dovetail Jigs

For those looking to streamline the process, dovetail jigs can be a valuable tool. These jigs guide your saw and chisel, ensuring consistent and accurate cuts.

Common Mistakes and How to Avoid Them

18. Inaccurate Measurements

One of the most common pitfalls in dovetail joinery is inaccurate measurements. Always measure twice and cut once to avoid costly mistakes.

19. Poor Saw Technique

A steady hand and proper saw technique are crucial. Practice cutting straight lines and maintaining control over your saw.

20. Rushing the Process

Patience is essential in dovetail joinery. Take your time with each step to ensure the highest quality joints.

Applications of Dovetail Joinery

21. Furniture Making

Dovetail joinery is a hallmark of fine furniture making. Use it to construct drawers, cabinets, and carcasses for a sturdy and elegant finish.

22. Box Making

From jewelry boxes to tool chests, dovetail joinery is ideal for creating durable and beautiful boxes.

23. Decorative Items

Beyond functional items, dovetail joints can be used in decorative pieces like picture frames and wall art, showcasing your craftsmanship.

Maintaining Your Dovetail Joints

24. Regular Inspection

Periodically inspect your dovetail joints for any signs of wear or damage. Early detection can prevent more significant issues down the line.

25. Re-gluing

If a joint becomes loose, re-glue it promptly to maintain the integrity of the piece.

26. Finishing Techniques

Applying a protective finish can enhance the appearance and longevity of your dovetail joints. Consider using varnish, oil, or wax based on your project needs.

The Future of Dovetail Woodworking

27. Innovations in Tools and Techniques

As technology advances, new tools and techniques are emerging in dovetail joinery. Stay updated with the latest trends to continuously improve your skills.

28. Sustainability and Woodworking

Embrace sustainable practices by using responsibly sourced wood and minimizing waste in your dovetail woodworking projects.

Conclusion

Dovetail woodworking is a rewarding and enriching craft that combines precision, creativity, and skill. By mastering the techniques and understanding the principles behind dovetail joinery, you can create stunning, durable pieces that stand the test of time. Whether you’re a seasoned woodworker or a beginner, there’s always something new to learn and explore in the world of dovetail woodworking.

For your “Free” 2 in 1 Folding Picnic Table Bench Plan – Click Here.

FAQs

1. What wood is best for dovetail joinery?

Hardwoods like oak, maple, and cherry are ideal for dovetail woodworking due to their durability and fine grain.

2. Can I use dovetail jigs for all types of joints?

Dovetail jigs are versatile and can be used for most dovetail joints, though manual techniques might be preferred for more intricate designs.

3. How long does it take to master dovetail joinery?

The time to master dovetail woodworking varies based on your dedication and practice. With consistent effort, you can achieve proficiency within a few months.

4. Are dovetail joints stronger than other types of joinery?

Yes, dovetail joints are known for their strength and resistance to being pulled apart, making them one of the strongest types of joinery.

5. Can dovetail joinery be done with power tools?

While traditional dovetail woodworking is done with hand tools, power tools and jigs can significantly speed up the process and ensure precision.