Double sided tape for woodworking is an essential tool in this intricate and rewarding craft, recognized by both beginner and experienced woodworkers. Often overlooked, this simple yet versatile product has earned a crucial spot in workshops worldwide. Whether you’re securing a template, performing delicate work, or temporarily assembling projects, double-sided tape provides a wide range of uses that can significantly simplify your tasks and improve accuracy.

In this guide, we’ll walk you through everything you need to know about double-sided tape for woodworking: from what it is, to how to use it effectively, and how to choose the right type. Let’s dive in and explore why this tape could be the unsung hero of your next woodworking project!

What is Double-Sided Tape?

Double-sided tape is exactly what it sounds like: a tape that has adhesive on both sides. Unlike single-sided tape, which is often used to seal, bind, or protect surfaces, double-sided tape is designed to bond two surfaces together temporarily but effectively.

In woodworking, double-sided tape has become a crucial component for tasks where you need to hold wood pieces or templates together without causing damage or leaving residue. Its strength and versatility allow you to keep pieces in place without the need for clamps or other tools. Plus, since it comes in various thicknesses and adhesive strengths, you can find the perfect match for each specific task.

Why Use Double-Sided Tape?

You might be wondering, “Why not just use clamps?” While clamps have their place in woodworking, double-sided tape offers flexibility and convenience that clamps cannot always provide. Imagine working with a delicate template or small piece of wood. Using clamps could cause warping or denting, whereas double-sided tape provides a secure hold without damaging your materials.

Moreover, double-sided tape eliminates the risk of shifting or slipping, allowing for more precise work. Think of it as an extra set of hands—hands that are perfectly still, never tired, and always available.

Types of Double-Sided Tape

Not all double-sided tapes are created equal, and different woodworking tasks require specific types. Here are some common varieties you’ll encounter:

- Carpet Tape: While primarily designed for securing carpets, this tape is widely used in woodworking for its strong adhesion and ability to hold wood pieces together securely.

- Foam Double-Sided Tape: Foam tapes provide a cushioning effect, making them ideal for uneven surfaces or where slight flexibility is needed.

- Heavy-Duty Double-Sided Tape: For projects that require maximum holding power, heavy-duty tape can offer long-lasting adherence and support even for larger wood panels.

- Thin Double-Sided Tape: When you need a subtle, almost invisible bond between pieces, thin tape is a great option.

- Removable Double-Sided Tape: As the name suggests, this tape is designed to be easily removable without leaving a sticky residue, making it perfect for temporary applications.

How to Choose the Right Double-Sided Tape for Woodworking

Choosing the right double-sided tape depends on several factors. The first thing you’ll want to consider is the type of project you’re working on. Are you temporarily holding a template in place, or do you need to bond larger, heavier pieces of wood together? For heavier pieces, heavy-duty double-sided tape will provide the extra grip you need.

Next, think about the material you’re working with. Not all tapes adhere well to every type of wood or surface, so you’ll want to ensure that your tape is compatible. Additionally, for projects requiring temporary holds, removable or low-residue double-sided tape will prevent damage to your materials when you take it off.

Applications of Double-Sided Tape

There are numerous ways you can use double-sided tape in woodworking. Some common applications include:

- Holding Templates: When cutting or routing, you often need to keep a template in place. Clamps may get in the way, but double-sided tape allows you to secure the template without obstructions.

- Laminating Small Pieces: If you’re working with veneers or small pieces that need temporary adhesion before final assembly, double-sided tape is the perfect solution.

- Fixing Sandpaper: For tasks like sharpening tools or sanding delicate edges, double-sided tape can secure sandpaper to a flat surface or block, making it easier to handle.

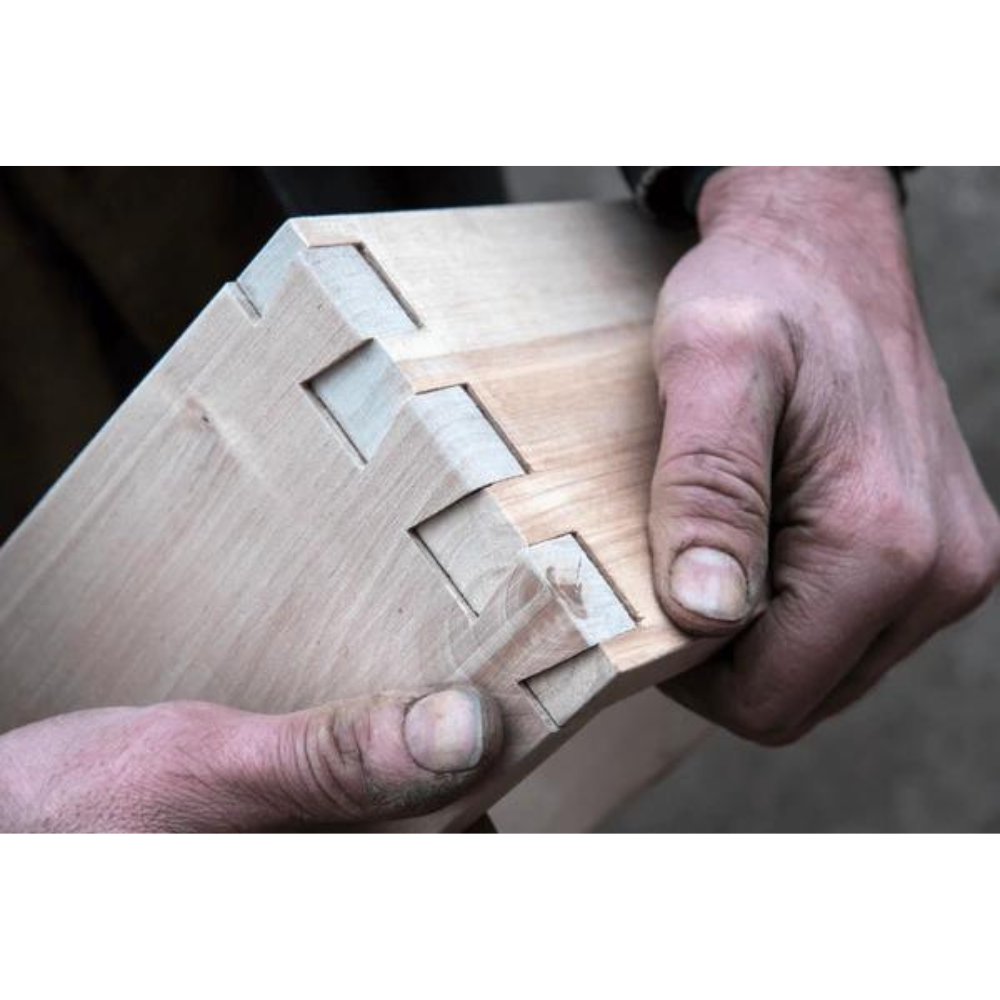

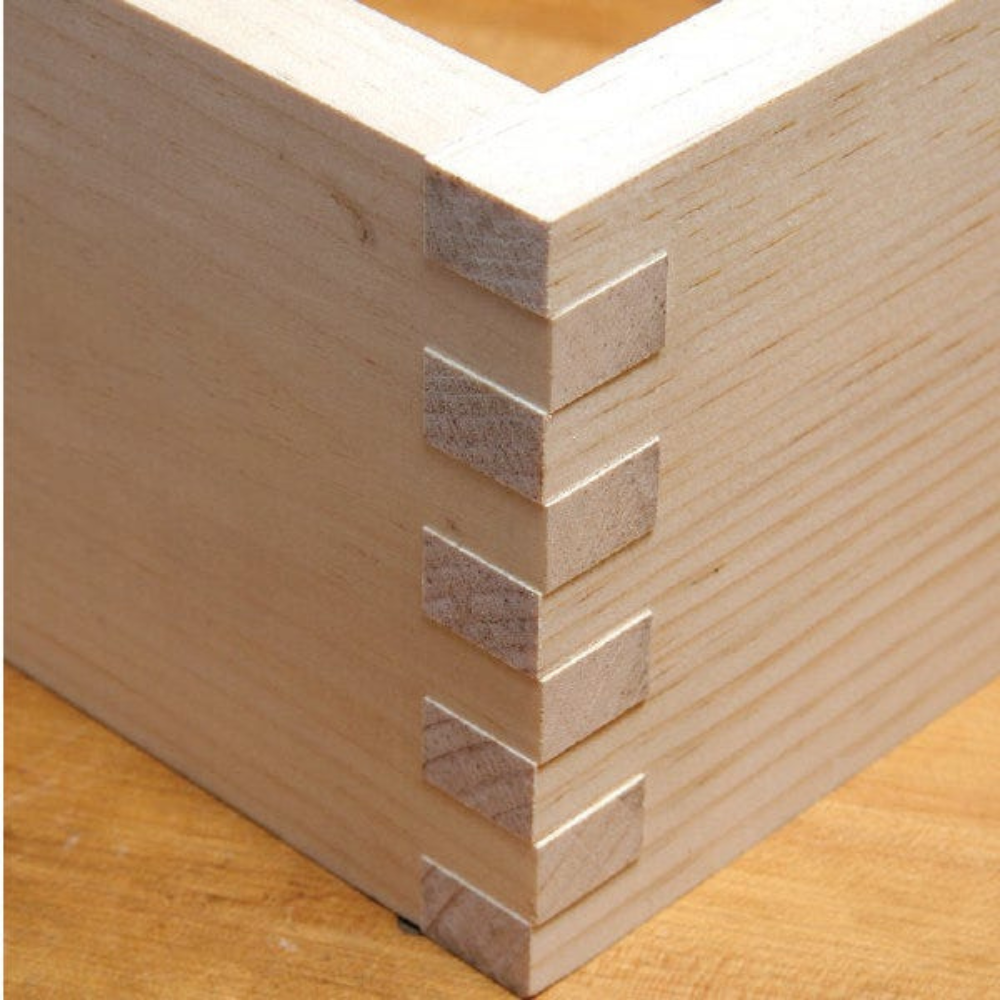

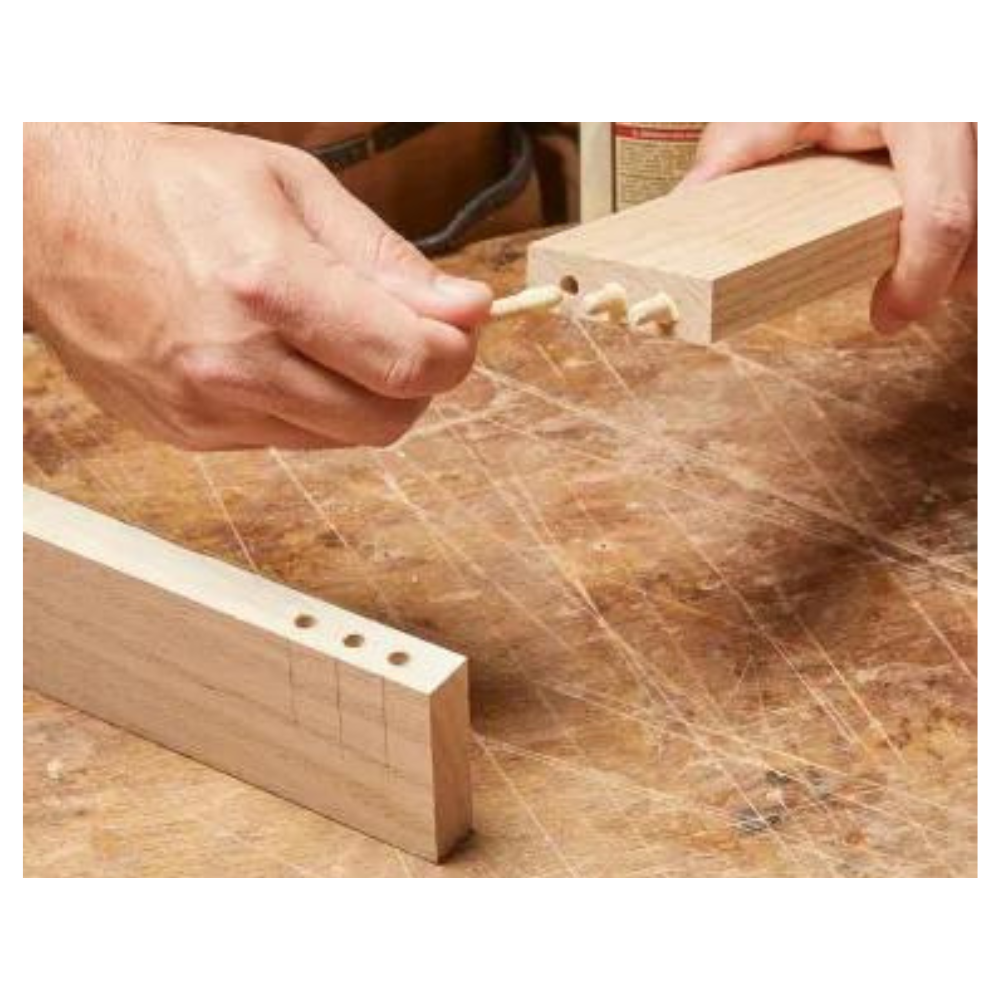

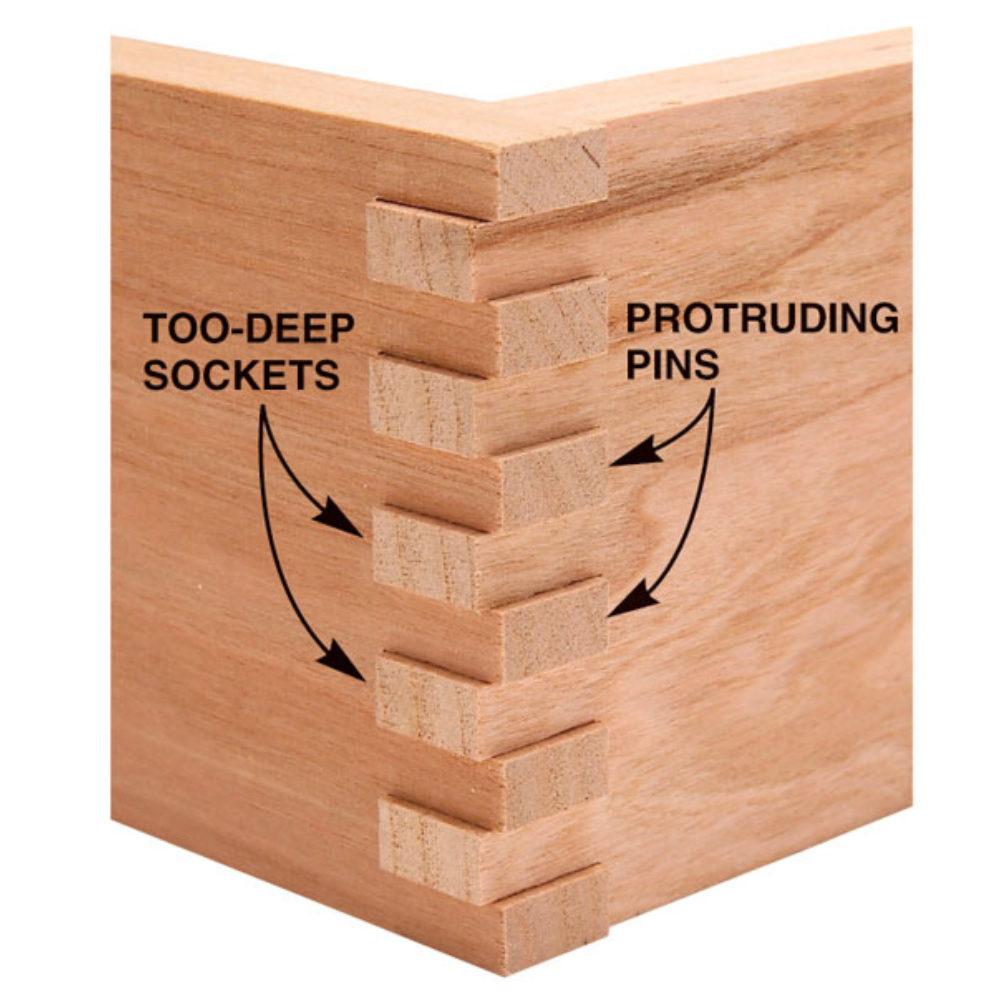

- Creating Temporary Joints: When you need to see how parts fit together before gluing or screwing, double-sided tape helps you assemble projects temporarily, allowing for adjustments.

- Jigs and Fixtures: Building jigs or temporary fixtures for your saw or drill press? Double-sided tape holds everything in place with minimal setup time.

How to Use Double-Sided Tape in Woodworking

Using double-sided tape is straightforward, but a few tips can help ensure the best results:

- Clean the Surface: Before applying the tape, make sure the wood surface is clean and free from dust or debris. This ensures a stronger bond.

- Apply Evenly: Roll out the tape in even, smooth lines. Avoid overlaps or wrinkles as these can create gaps or weak spots in the adhesion.

- Press Firmly: After placing the tape on the wood, press it down firmly to ensure it bonds well. Use a roller or your hands to apply even pressure.

- Remove Carefully: When it’s time to remove the tape, do so slowly and carefully to avoid pulling up any wood fibers or damaging the surface.

The Strengths and Weaknesses of Double-Sided Tape

As with any tool or product, there are advantages and disadvantages to using double-sided tape for woodworking. Understanding both sides can help you make an informed decision about when and how to use it.

Strengths:

- Versatility: Suitable for various applications, from holding templates to securing jigs.

- Non-Invasive: Unlike clamps, tape won’t leave marks or impressions on your workpieces.

- Ease of Use: Simply peel and stick—there’s no complex setup required.

- Precision: Holds objects in place without slipping or movement.

Weaknesses:

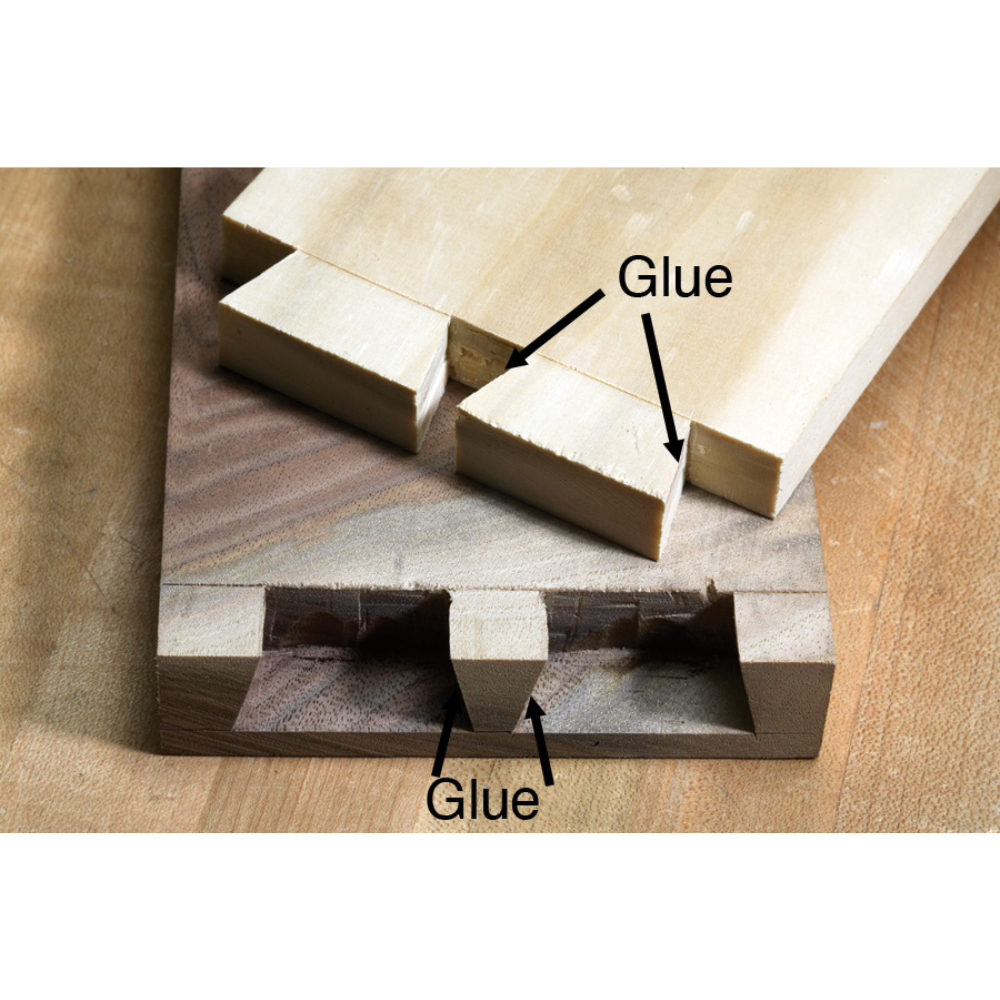

- Temporary: While great for temporary holds, double-sided tape isn’t a substitute for permanent bonding methods like glue or screws.

- Residue Risk: Some tapes may leave adhesive residue behind, especially if left on for an extended period.

- Not Suitable for Heavy Loads: Double-sided tape may struggle to support very heavy or large wood pieces.

When Not to Use Double-Sided Tape

Despite its versatility, there are certain situations where double-sided tape may not be the best choice. For example, when working with very heavy or thick wood panels, tape may not provide sufficient strength. In such cases, clamps or screws may be necessary to hold pieces together.

Additionally, for projects requiring permanent bonding, double-sided tape should not be relied upon. Wood glue, nails, or screws will provide a much stronger and more lasting hold.

How to Remove Double-Sided Tape Without Damaging Wood

Removing double-sided tape for woodworking can sometimes be tricky, especially if the tape has been on for a long time or has left residue. To minimize damage, here are some steps you can follow:

- Slow and Steady: Peel the tape back slowly, pulling at an angle to minimize the risk of pulling up wood fibers.

- Use Heat: A hairdryer or heat gun can soften the adhesive, making it easier to remove.

- Adhesive Remover: For stubborn residue, an adhesive remover or rubbing alcohol can help dissolve the glue without damaging the wood.

- Sand the Surface: If necessary, gently sand the area where the tape was applied to restore the wood’s smooth finish.

Alternatives to Double-Sided Tape

While double-sided tape is an excellent option for many woodworking tasks, there are alternatives that may be better suited for certain projects. Some common alternatives include:

- Clamps: Ideal for heavy-duty applications or when you need a very strong hold.

- Hot Glue: Provides quick adhesion and is easily removable, but it may not be suitable for delicate surfaces.

- Blue Painter’s Tape: Often used for marking or temporary holds without leaving residue.

Top Brands of Double-Sided Tape

When choosing a double-sided tape for woodworking, the brand can make a significant difference in terms of quality and reliability. Some of the top brands known for producing high-quality double-sided tape for woodworking include:

- Scotch: Known for its variety of tape products, Scotch offers durable, strong double-sided tapes that work well in woodworking projects.

- 3M: A leader in adhesive technologies, 3M tapes are trusted for their strength, durability, and range of applications.

- XFasten: A more specialized tape brand that focuses on creating durable, woodworking-specific double-sided tapes.

- Shurtape: Shurtape produces heavy-duty double-sided tapes designed for both temporary and long-term woodworking applications.

Common Mistakes to Avoid When Using Double-Sided Tape

While using double-sided tape for woodworking is relatively simple, there are a few common mistakes that can reduce its effectiveness. Here are some things to watch out for:

- Applying to Dirty Surfaces: Adhesive tape requires a clean surface to bond effectively. If dust or sawdust is present, the tape won’t stick properly.

- Using the Wrong Type of Tape: Not all tapes are created equal. Make sure you choose the right kind for your specific project needs.

- Leaving Tape on Too Long: While double-sided tape can be left in place temporarily, leaving it on for too long can cause adhesive residue or damage to the wood.

How to Store Double-Sided Tape for Longevity

To ensure your double-sided tape stays in good condition, it’s essential to store it correctly. Keep it in a cool, dry place, away from direct sunlight. Heat can cause the adhesive to degrade, making the tape less effective when you need it. You should also avoid moisture, as it can cause the tape to lose its stickiness or become damaged.

Conclusion: Why Double-Sided Tape is a Must-Have Tool

In conclusion, double-sided tape for woodworking is an indispensable tool for anyone looking to improve the precision and ease of their projects. Whether you’re a professional carpenter or a weekend hobbyist, this tape offers a simple solution for temporary holds, template work, jig making, and more. Its versatility, ease of use, and non-invasive nature make it a go-to choice for various woodworking tasks. Keep a few different types of double-sided tape in your toolbox, and you’ll find yourself reaching for it time and time again.

FAQs About Double-Sided Tape for Woodworking

1. Can double-sided tape be used for heavy-duty woodworking projects?

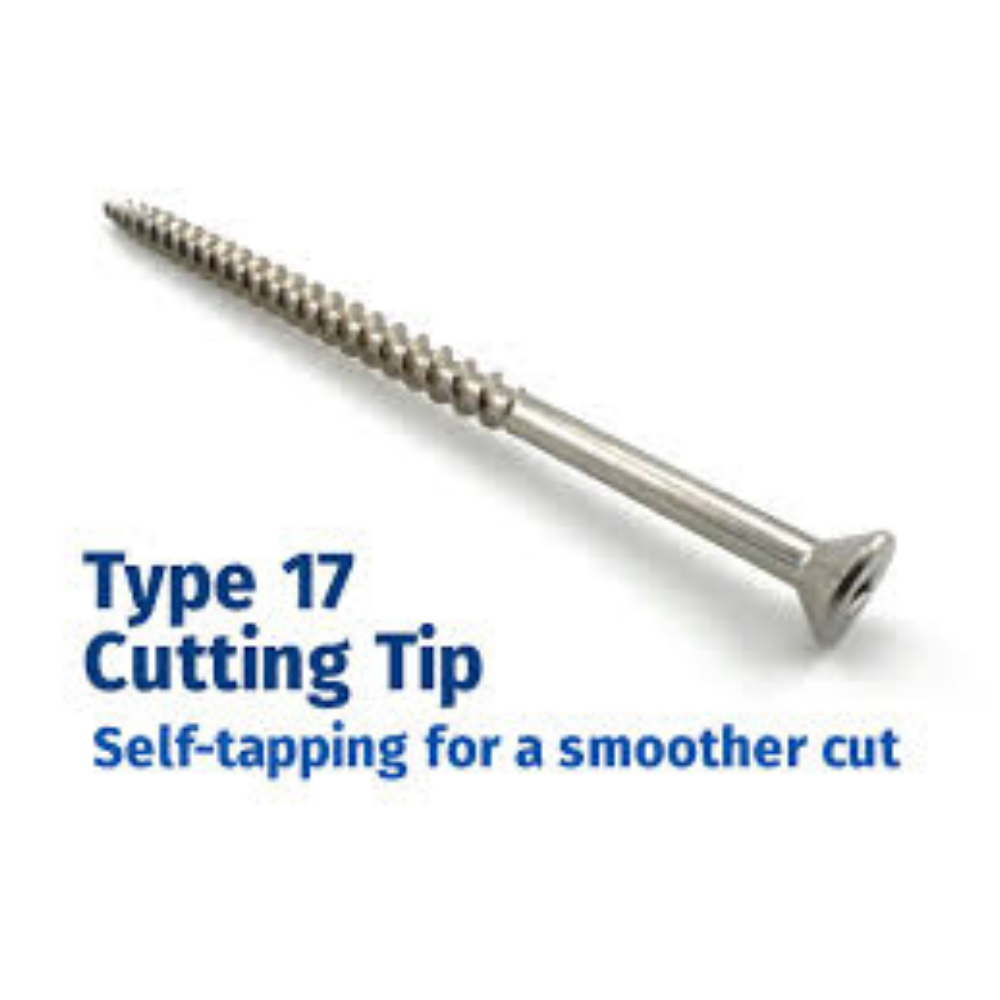

While double-sided tape can handle small to medium-sized woodworking tasks, it’s not designed to hold extremely heavy loads for extended periods. For heavy-duty projects, clamps or screws are better suited.

2. Will double-sided tape damage wood?

Generally, double-sided tape for woodworking is designed to be gentle on wood surfaces. However, if left on for too long or if removed incorrectly, it can pull up wood fibers or leave adhesive residue. Always remove it carefully and use the appropriate type of tape for the task.

3. How do I prevent double-sided tape from leaving a residue?

To prevent residue, use removable or low-residue double-sided tape. Additionally, avoid leaving the tape on for longer than necessary and clean the wood surface before applying the tape.

4. Can double-sided tape hold up in humid or hot conditions?

Certain tapes, especially foam-based or heavy-duty varieties, are designed to withstand higher temperatures or humidity. However, excessive heat and moisture can weaken some tapes, so it’s essential to choose a tape suited for your environment.

5. How do I remove double-sided tape from wood without damaging the surface?

The key is to remove the tape slowly and steadily, using heat if necessary. If residue is left behind, rubbing alcohol or a commercial adhesive remover can help clean the surface without causing damage.